Infrared thermal imaging monitors the temperature distribution of the trolley and grate bars at the rear of the sintering machine and the cooling status of the sintered ore, and warns of equipment overheating failures and abnormal sintered ore quality, helping to optimize the sintering process and improve production efficiency. In metallurgical plants (especially steel enterprises), sintering machines are the core equipment of the sintering process. They are mainly used to make sintered ore with a certain strength and particle size from raw materials such as iron ore powder, fuel (such as coke powder), and flux (such as lime), providing high-quality charge for blast furnace ironmaking.

The HIRDA-S series sintering machine tail thermal camera online temperature detection and analysis system is a special equipment specially used in high temperature environment. The system consists of infrared thermal imaging movement, high temperature resistant infrared thermal imaging lens, automatic retraction protection device, furnace wall installation kit, air filtration system and field equipment box, algorithm server and intelligent temperature measurement software.

The high temperature resistant thermal image camera lens is installed in a retractable metal protective cover. The high temperature resistant infrared thermal imaging lens is directly extended into the tail of the sintering machine through the retractable device. The infrared thermal imaging core stays outside the furnace to realize real-time monitoring of the cross-section temperature of the sintered cake at the tail of the sintering machine.

The shield is cooled by compressed cooling air or cooling water, so that the infrared lens can work at a more suitable temperature; at the same time, the lens is purged to prevent dust in the furnace from adhering to the lens protection window; the system has a built-in high-protection circuit, which will retract the lens once the cooling gas or cooling water circulation is abnormal to prevent damage by the high temperature in the furnace.

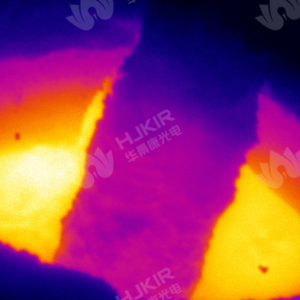

The infrared image of the sintered cake section at the tail discharge area of the sintering machine can directly reflect the information of the material layer status, which is a comprehensive response of the sintering production process and can be used as the main basis for controlling the heat level in the sintering material layer. The system determines the sintering quality indicators and the reasonable values of various operating parameters based on the established sintering endpoint prediction model through the brightness, color, size, distribution and position of the red heat bands in the adjacent tail sections of the sintering machine, the integrity of the sintered cake discharge and the size of the dust.

The sintering endpoint prediction model accurately forms the red layer image of the tail section through infrared thermal imaging, uses image preprocessing to extract the area, center of gravity, perimeter and other features of the red fire layer in the sintering tail section image, and extracts the characteristic parameters such as the average brightness and average area value of the sintering pores related to the FeO content. By establishing the inference rules related to the sintering tail section image features and combining them with the extracted characteristic parameters, the method of comparing the brightness of the red fire layer between each frame of the sintering tail video is used to accurately find the key frame of the sintering tail section. The sintering quality information and the image are displayed at the same time. At the same time, data analysis, FeO prediction and other technologies are used to provide decision-making information for sintering control production, guiding the production control operations of the sintering endpoint model and ignition optimization model.

▲ Sintered cake cross section infrared image acquisition and temperature distribution display;

▲ Analysis of relevant information on the tail section of sintering machine;

▲ Establishment of a model for the change trend of FeO content in sintered ore;

▲ Endoscopic high temperature resistant stainless steel protective cover can probe into the tail cover to collect data;

▲ The telescopic length can be customized according to the wall thickness;

▲ Ir video camera has spiral air curtain design, no dust accumulation on the lens;

▲ Automatically exit the protection device and exit the fault indication;

▲ Automatic exit in case of over temperature, under voltage or power failure.

Short-wave temperature measurement (ir camera for sale) has the following significant advantages, especially in the fields of industrial detection, remote sensing monitoring, high-temperature measurement, etc.:一. Fast response speed, suitable for dynamic measurement 二、Small environmental interference and high measurement accurac...

infrared thermal imaging Real-time temperature monitoring Predictive maintenance Improve product quality Safety warning function

LASER Photonics China 2025: A new chapter of optoelectronic technology innovation and global cooperation From March 11 to 13, 2025, the most influential event in Asia's optoelectronics industry, LASER Photonics China, will be held in Shanghai New International Expo Center. As the flagship exhibition in China's laser, optics and optoe...