Infrared thermal imaging helps with molten iron transportation safety warning, pre-furnace treatment process optimization and equipment thermal damage prevention and control by monitoring the temperature distribution and surface condition of molten iron. The process of molten iron and tanks (such as ladles and torpedo tanks) runs through the key links of ironmaking, transportation, pretreatment and steelmaking, and is the core link between blast furnace ironmaking and converter steelmaking.

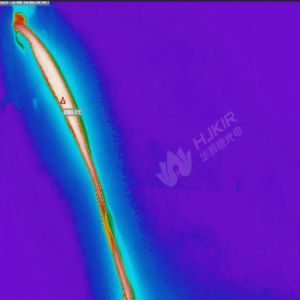

HIRDA-MI molten iron temperature continuous detection system is a high-tech system specially used for detecting molten iron temperature and conducting intelligent analysis. The system consists of a high-temperature infrared thermal imaging thermometer, a field equipment box, an image algorithm server, and a client management software. Each taphole is equipped with a taphole molten iron continuous temperature measurement device. The taphole molten iron continuous temperature measurement device is installed at a suitable position near the taphole and is cooled and dustproofed by compressed air. When tapping iron, the taphole molten iron continuous temperature measurement device can simultaneously obtain the image and temperature of the molten iron flow, can capture clear molten iron flow images, can measure accurate taphole molten iron flow temperature field distribution (including taphole molten iron temperature and iron slag temperature), and display real-time infrared video of the molten iron flow when tapping iron.

The data obtained by the continuous temperature measurement system of molten iron is transmitted to the industrial computer in the main control room of the blast furnace through optical fiber for real-time display of the molten iron temperature and data storage. It can automatically detect the iron-out status of each taphole in real time and record the start time, end time and duration of each taphole.

System Features

1. Thermal imaging device has high temperature resistant design, can withstand up to 200℃ ambient temperature;

2. IR thermal camera high protection level, protection grade up to IP66;

3. Automatic window cleaning, no need for manual window cleaning;

4. Full-screen real-time temperature measurement with wide coverage;

5. Not only dependent on the system platform, you can directly log in to the web page IP to access images and configurations, and can directly output alarm signals to PLC or alarms;

6. Support GB28181, onvif protocol, can be connected to mainstream NVR;

7. Temperature data can be connected to LED screen and PLC;

8. Electric/automatic focus, focus operation can be performed at any time through software;

9. Cam thermal's temperature range 800℃ to 1800℃;

10. Temperature measurement accuracy ≤1%;

11. Supports modbus protocol and can be connected to DCS system to transmit temperature data.

HJKIR developed a new type of continuous temperature measurement system for molten iron, which can directly measure the temperature of the iron flow at the taphole during tapping and more directly and accurately represent the state and change process of the physical heat of the furnace. At the same time, it has the outstanding characteristics of...

Optimize the thermal efficiency of the sintering process, reduce energy consumption, adjust the amount and distribution of solid fuel according to the temperature distribution of the material layer, avoid heat waste caused by excessive fuel or incomplete sintering caused by insufficient fuel, and reduce fuel consumption per ton of o...