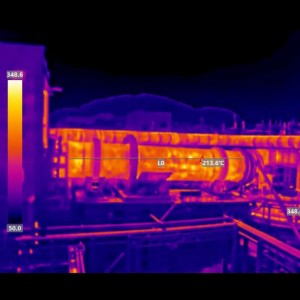

Infrared thermal imaging can monitor the temperature field of the rotary kiln body in real time, warn of refractory material damage and abnormal sintering of materials in the kiln, and provide key data support for kiln body life maintenance and calcination process optimization. The rotary kiln shell is the core component of the cement plant's clinker burning system. Its main process revolves around the heating, calcination and chemical reaction of materials in the kiln.

System features:

1.Thermo camera has high-temperature resistant design, withstanding up to 200℃ ambient temperature

2.High degree of protection up to IP66

3.The window is automatically blown, and there is no need to manually clean the window regularly

4.Full-screen real-time temperature measurement, wide coverage;

5.Thermal image camera does not depend on the system platform, and can directly log in to the IP page to access the image and configuration, and can directly output the alarm signal to the PLC or alarm;

6.Infrared thermography camera support onv if protocol, can access mainstream NVR;

7.The temperature data can be connected to the LED screen and PLC; Motorized/autofocus, focus operation through software at any time;

8.The temperature measurement range can be customized, and the maximum support is -40℃ to 2000℃;

9.The temperature measurement accuracy is better than±2℃ or±2%;

10.It supports modb us protocol and can be connected with the DCS system for temperature data transmission.

Every kiln operator knows that proper maintenance makes the difference between consistent results and costly downtime. In this guide, we'll explore how three specialized tools - small infrared cameras, kiln cement, and kiln Portland cement - can transform your maintenance routine and keep your kiln operating at peak efficiency. 1. Pr...

infrared thermal imaging technology improved detection efficiency, real-time monitoring, preventive maintenance, safety improvement and economic improvement