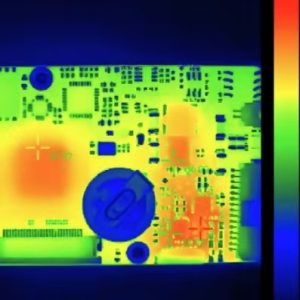

Thermal imaging camera are employed to monitor the temperature of critical mechanical and electrical assets within warehouses. This includes conveyor systems, motors, and electrical panels. By detecting temperature anomalies and hotspots, these devices help prevent equipment failures and reduce unplanned downtime. For instance, the SmartIR system allows for continuous monitoring, enabling predictive maintenance and extending the lifespan of assets by identifying potential issues early

In battery warehouses, Thermal imagers imagers play a crucial role in identifying abnormal hotspots that may indicate battery faults. These devices can detect temperature changes during storage and charging processes, helping to prevent fire hazards. Regular inspections using thermal imaging can track battery health and optimize storage conditions to ensure safety and efficiency

Warehouses that handle flammable materials or chemicals benefit from infrared technology for early fire detection. For example, a major wood and paper manufacturer implemented infrared monitoring systems after experiencing a fire incident. This proactive approach allows for real-time alerts when high-temperature areas are detected, significantly enhancing safety measures

Infrared illuminators are used for surveillance in warehouses, especially during low-light conditions. They enhance the visibility of security cameras, allowing for effective monitoring of perimeters and preventing unauthorized access even in complete darkness

Thermal image camera technology assists in monitoring the condition of temperature-sensitive products stored in warehouses. By identifying temperature fluctuations, warehouse operators can ensure that goods are stored under optimal conditions, thus maintaining product quality and reducing waste

In summary, the integration of infrared devices in warehouse operations not only enhances safety but also improves efficiency and reliability through advanced monitoring capabilities.

infrared thermal imaging technology Real-time monitoring and fault location efficiency Safety assurance

infrared thermal imaging technology improved detection efficiency, real-time monitoring, preventive maintenance, safety improvement and economic improvement

Infrared cameras are essential tools in diagnosing and troubleshooting automotive circuit boards.Integration with Automated Inspection Systems