Wind power generation is a new energy utilization method that converts the kinetic energy of wind into electrical energy.

Working principle:

The working principle of wind power generation is to use wind power to drive the windmill blades to rotate. The wind wheel rotates under the action of wind power, converting the kinetic energy of wind into mechanical energy of the wind wheel shaft, and then increasing the speed of rotation through the speed increaser, which finally prompts the generator to generate electricity and output AC power.

Common problems of wind power generation mainly include the following aspects:

The application of infrared thermal imaging technology in wind power generation has many significant benefits, mainly including improved detection efficiency, real-time monitoring, preventive maintenance, safety improvement and economic improvement.

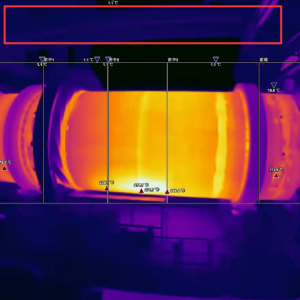

First, thermal heat camera technology has the advantage of non-contact detection. It does not need to directly contact the surface of the wind power generation equipment. It obtains the temperature distribution by measuring the infrared radiation on the surface of the equipment, thereby avoiding the need to shut down or dismantle the equipment, reducing interference and downtime during the detection process, and improving the efficiency and convenience of detection.

Second, cheap thermal camera technology can achieve real-time monitoring. It can monitor the temperature distribution of wind power generation equipment in real time and display it in the form of color images, helping operators to intuitively observe the temperature difference on the surface of the equipment, timely detect abnormal conditions and take corresponding measures to avoid failures and damage caused by overheating or uneven heating of the equipment. In addition, infrared thermal imaging technology helps preventive maintenance. Through regular thermal imaging detection, the health status of the equipment can be evaluated, potential problems such as cracks, wear, overheating, etc. can be found, so that repair or replacement measures can be taken in time to extend the service life of the equipment and improve reliability and safety. In terms of safety, infrared thermal imaging technology reduces the risk of personnel contacting the equipment. Since there is no need to directly contact the equipment, accidental injuries caused by high-speed rotating blades or complex operating environments are avoided. At the same time, no electromagnetic radiation or pollution will be generated during the detection process, which is harmless to the environment and human health.

Finally, thermal video camera price technology also has economic advantages. Although the initial investment may be high, preventive maintenance reduces the risk of serious failures and repair costs, improving the economy of wind power generation systems.

Maintaining your kiln properly ensures consistent results and prevents costly damage. Whether you're a ceramic artist or industrial operator, understanding proper unloading and maintenance techniques is crucial. This guide highlights three essential components for optimal kiln performance: small infrared cameras, kiln cement, and kil...

Shocking Truth:Over 25% of electrical fires start from simple connection issues that thermal cameras can spot weeks in advance. Real-World Example:During a factory maintenance check, a thermal camera reveals a circuit breaker glowing at 75°C (normal <35°C). Closer inspection shows a corroded connection causing overheating, with ...

Infrared thermal imaging thermometer solution monitoring continuous casting process non-contact infrared measurement detection technology, HJK infrared thermal imager temperature range work in -20℃~+60℃, temperature measurement range from -20℃ to 2500℃ and with High protection level, can reach IP66, convient modes like optional Electric/automati...