Ethylene Cracking Furnace

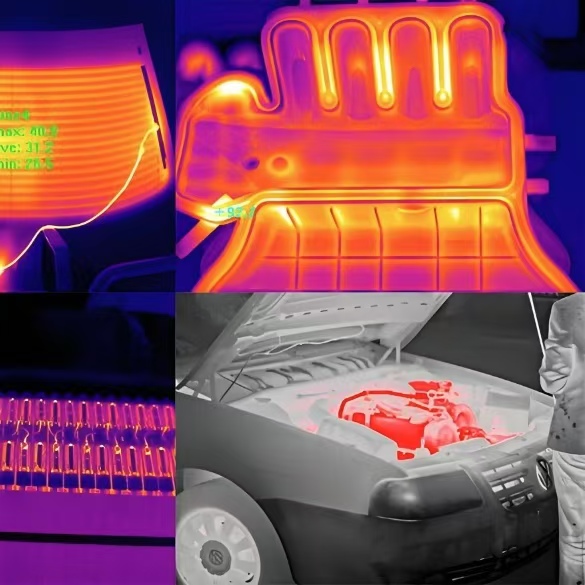

Infrared thermal imaging cameras offer significant advantages for inspecting ethylene cracking furnaces, a critical component in petrochemical production. These benefits enhance safety, operational efficiency, and equipment longevity in high-temperature, high-risk environments. Here are the key advantages:

- Critical Safety and Integrity Monitoring:

Ethylene cracking furnaces operate at 800–950°C, with refractory linings (ceramic or brick) protecting the steel shell from extreme heat. Infrared imaging identifies hot spots caused by cracks, erosion, or delamination in the refractory (e.g., a 150°C temperature spike on the furnace exterior), enabling proactive repairs before catastrophic failures (e.g., shell melting or gas leaks).

Impact: Early detection can prevent $1M+ in unplanned shutdowns and safety incidents by addressing lining damage 3–6 months before visual inspection would reveal issues.

- Flame Uniformity and Air-Fuel Ratio Analysis:

Uneven flame distribution or poor air-fuel mixing in burners leads to incomplete combustion, increased CO emissions, and reduced ethylene yield. Thermal imaging visualizes flame temperature profiles (e.g., a "cool" yellow flame indicating excess fuel or a "hot" blue flame with optimal combustion), allowing operators to fine-tune gas flow and air intake.

Data: A petrochemical plant improved ethylene yield by 5% and reduced fuel consumption by 8% after optimizing burner performance with thermal imaging data.

- Coke Deposition Monitoring:

Coke buildup on furnace tubes (a byproduct of cracking) reduces heat transfer efficiency. Infrared imaging detects temperature discrepancies (e.g., cooler spots on tubes with heavy coke deposits), guiding timely decoking schedules to maintain throughput.

- Remote Inspection of High-Risk Zones:

Ethylene furnaces involve flammable gases (e.g., methane, ethylene) and high pressures, posing explosion risks. Thermal imaging allows operators to inspect burners, tubes, and seals from 10+ meters away, eliminating the need for close proximity during operation.

- Immediate Leak Detection:

Invisible leaks of hydrocarbons or steam (e.g., from cracked tubes or faulty valves) can be visualized as thermal anomalies. Specialized infrared cameras with gas-specific filters (e.g., for methane or water vapor) identify leaks in real time, enabling rapid shutdowns to prevent fires or toxic exposures.

- Heat Loss Identification:

Damaged insulation, loose seals, or faulty expansion joints cause heat dissipation. Thermal imaging maps surface temperatures to pinpoint inefficiencies (e.g., a 200°C hot zone on an uninsulated flange), guiding targeted repairs.

Example: A refinery reduced natural gas consumption by 10% after reinforcing furnace insulation based on thermal data, saving $200,000 annually in fuel costs.

- Emissions Compliance:

Optimized combustion via thermal imaging reduces NOx, CO, and VOC emissions, helping plants meet EPA, EU ETS, or local environmental regulations. Quantitative temperature data provides auditable records for compliance reporting.

- Trend Analysis for Proactive Repairs:

Historical thermal data tracks gradual changes (e.g., a 3°C/year increase in tube surface temperature, indicating coke buildup or tube degradation), enabling scheduled maintenance during planned outages instead of reactive shutdowns.

Impact: Predictive maintenance reduces unplanned downtime by 40–60%, with ethylene furnace outages costing ~$500,000 per day in lost production.

- Component Health Monitoring:

Thermal imaging evaluates critical components like burners, blowers, and temperature sensors. For example, a malfunctioning burner may appear cooler than others, signaling electrical or mechanical issues (e.g., faulty igniters or blocked fuel nozzles) before complete failure.

- Uniform Temperature Control:

Inconsistent furnace temperatures lead to uneven cracking, producing off-spec products (e.g., lower ethylene/propane ratios). Real-time thermal monitoring ensures uniform heating across all tubes, minimizing product variability and improving yield consistency.

- Tube Life Extension:

Overheating or localized hot spots accelerate tube corrosion and creep failure. Thermal imaging prevents excessive temperature exposure, extending tube lifespan by 10–15% and reducing replacement costs (e.g., $50,000–$100,000 per tube).

Infrared thermal imaging is indispensable for maintaining the safety, efficiency, and profitability of ethylene cracking furnaces. By enabling early fault detection, optimizing combustion, and supporting predictive maintenance, it addresses the unique challenges of high-temperature petrochemical operations. For industries where every hour of downtime translates to massive revenue loss, thermal imaging provides a robust tool to mitigate risks, reduce costs, and ensure sustainable production.