Hazardous waste kiln, also known as rotary kiln, is one of the main equipment for treating hazardous waste. It is a special equipment for treating hazardous waste. It has various types and is classified according to the treatment object and process characteristics. Hazardous waste kilns can be divided into solid waste hazardous waste kilns and liquid waste hazardous waste kilns according to the different treatment objects. Solid waste hazardous waste kilns are mainly used for incineration, melting and other treatment methods, which can effectively reduce the volume of waste and carry out harmless treatment; while liquid waste hazardous waste kilns focus on high-temperature distillation or cracking of liquid waste.

The working principle of the hazardous waste kiln is to convert hazardous waste into harmless substances by high-temperature oxidation and decomposition. The rotary kiln is mainly composed of a rotary drum, a combustion chamber, a flue gas purification device, etc. Hazardous waste is loaded into the rotary kiln, oxidized and decomposed at high temperature to produce high-temperature combustion gas, and harmless gas and water vapor are discharged after being treated by the flue gas purification device.

The advantages of hazardous waste rotary kiln include simple equipment, reliable operation, wide range of material adaptability and small investment. However, its disadvantage is that the operation and maintenance are relatively complicated, and the skills required of the operators are relatively high.

Common problems of hazardous waste kilns mainly include the following aspects:

- Low treatment efficiency: The rotary kiln has poor treatment effect and high waste residual rate. This may be due to excessive feeding, resulting in insufficient temperature or insufficient residence time.

- Improper temperature control: The temperature of the rotary kiln is unstable, and overheating or low temperature occurs frequently. This may be due to insufficient or excessive fuel supply, resulting in incomplete combustion or excessive temperature.

- Flue gas emission problem: Flue gas emission does not meet the standard and affects the environment. This may be due to the failure of the flue gas purification device or the unqualified quality.

- Rotary kiln coking problem: Rotary kilns that have been incinerated for a long time may coke, resulting in a shortened service life, incomplete incineration, leaving a large amount of residue, and polluting the air.

- Poor feeding sealing: During the feeding stage, if the sealing is not good, hazardous waste gas may be emitted into the air, affecting the health of the treatment personnel and environmental pollution.

The application of infrared thermal imaging in hazardous waste kilns has the following benefits:

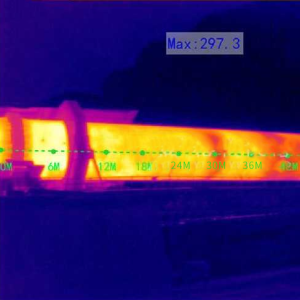

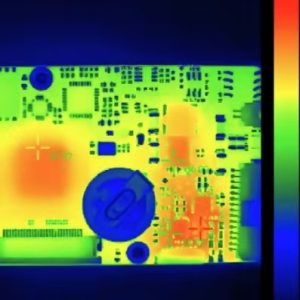

- Real-time temperature monitoring and fault detection: Thermal imaging video camera technology can monitor the temperature distribution inside the hazardous waste kiln in real time, detect abnormal temperature areas in time, prevent overheating and uneven temperature, and improve incineration efficiency and safety. In addition, by observing infrared images, abnormal hot spots in equipment and pipelines can be quickly discovered, and repair measures can be taken in time to avoid equipment failure and production interruptions.

- Energy saving optimization: Infrared thermal imaging technology, supported by insights from an IR camera, can help monitor temperature distribution and heat loss in the kiln, identify heat distribution patterns and loss pathways, and propose targeted energy-saving improvements. By leveraging data from such cameras—with considerations for IR camera price impacting initial investment—operators can optimize energy utilization efficiency, reduce energy consumption, and lower long-term operating costs.

-

Safety monitoring: Infrared thermal imaging technology, enabled by a thermal vision camera, can monitor the temperature distribution inside the incineration kiln in real time, detect abnormal conditions promptly, and avoid potential safety hazards. While evaluating the thermal vision camera price, operators should consider its role in preempting costly shutdowns and safety incidents. Additionally, monitoring the discharge port temperature and exhaust gas hotspots ensures environmental pollution control meets standards, aligning with regulatory compliance goals.

Emission monitoring: A thermal vision camera integrated into the system monitors the temperature distribution of the incineration kiln’s chimney or emission port, enabling timely detection of abnormal gas emissions. Although the thermal vision camera price represents an initial investment, the long-term benefits include reduced environmental fines and optimized emission treatment costs, ensuring sustainable compliance with pollution control standards.

- Fire prevention: Infrared thermal imaging technology can monitor the temperature distribution in the kiln in real time, warn of possible fire locations, provide important basis for fire prevention and control, and ensure the safety of personnel and the normal operation of equipment.

- Maintenance management: Through regular thermal imaging detection, potential fault points in equipment or pipelines can be found, and maintenance and repair can be carried out in time to extend the service life of equipment and reduce the risk of production interruption.

- Non-contact monitoring: Infrared thermal imaging technology obtains temperature information by measuring the infrared radiation of objects, without contact with hazardous waste, ensuring the safety of operators and avoiding the risk of pollution or spread of pollutants.

- High sensitivity and wide temperature measurement range: The infrared thermal imaging system has high sensitivity and can warn before a fire occurs, effectively preventing fire accidents. Its wide temperature measurement range is suitable for monitoring needs in different environments.

- Remote monitoring and intelligent alarm: The infrared monitoring system supports online remote monitoring, and multiple devices are connected to the network using background software, which reduces the monitoring cost of on-site personnel. The system can be linked with other safety equipment such as the fire alarm system. Once an abnormal situation is found, it can automatically trigger an alarm and take corresponding emergency measures.

- Data storage and analysis: The infrared monitoring system can store a large amount of monitoring data, analyze and process it, and provide data support for long-term tracking and evaluation of hazardous waste treatment and storage processes.

In summary, the application of infrared thermal imaging technology in hazardous waste kilns has many advantages and can significantly improve the safety and efficiency of hazardous waste treatment.