Infrared thermal imaging cameras offer significant advantages for inspecting glass melting furnaces, leveraging non-destructive, real-time thermal analysis to enhance safety, efficiency, and maintenance in glass production. Here are the key benefits:

- Identify Hotspots and Wear:Infrared imaging detects subtle temperature variations on the furnace exterior, signaling thinning or cracks in the refractory lining (e.g., brickwork or insulation).

- Example:A damaged liner allows heat to escape, creating visible "hotspots" on the furnace shell. Early detection prevents catastrophic failures (e.g., molten glass leaks) and costly downtime.

- Extend Liner Lifespan:By mapping thermal patterns, operators can optimize repair schedules and replace only affected sections of the liner, reducing maintenance costs.

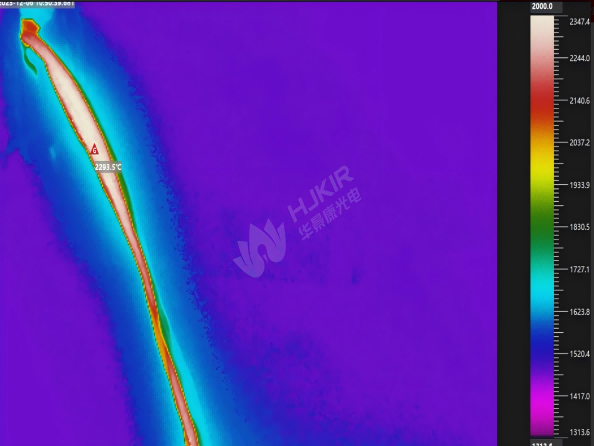

- Analyze Flame and Heat Distribution:Infrared cameras visualize flame patterns and temperature uniformity inside the furnace, ensuring optimal fuel combustion (e.g., natural gas, oil) and heat transfer to the glass melt.

- Benefit:Imbalanced heating can cause glass defects (e.g., uneven viscosity, bubbles). Thermal imaging helps adjust burner positioning or fuel-air ratios for consistent melting.

- Reduce Energy Waste:Inefficient combustion leads to higher energy consumption. Thermal data identifies underperforming burners or air leaks, enabling targeted adjustments to lower fuel costs.

- Safe, Remote Monitoring:Infrared cameras operate non-contact, allowing operators to assess high-temperature furnaces (often exceeding 1,500°C) from a safe distance, avoiding risks from direct exposure to molten glass or toxic fumes.

- Instant Diagnostics:Real-time thermal maps highlight issues like clogged burners, refractory erosion, or insulation gaps as they occur, enabling rapid response to prevent production disruptions.

- Evaluate Heating Elements and Valves:Thermal imaging detects overheating in electrical heaters, gas valves, or blower systems, predicting failures before they occur.

- Use Case:A failing blower motor emits abnormal heat, visible in infrared images. Proactive replacement prevents sudden furnace shutdowns and glass batch spoilage.

- Track Thermal Fatigue:Repeated heating/cooling cycles cause stress in furnace structures. Infrared data monitors gradual temperature changes to identify sections at risk of structural failure.

- Optimize Melting Zones:Uniform furnace temperature is critical for producing defect-free glass (e.g., clear sheets, optical fibers). Thermal imaging verifies that the melt pool maintains consistent temperatures, reducing variations in glass composition or clarity.

- Prevent Batch Contamination:Hotspots in the liner can cause localized overheating, leading to chemical reactions (e.g., refractory corrosion) that contaminate the glass. Early detection preserves material purity.

- Targeted Repairs:Infrared data pinpoints exact locations of damage (e.g., a 20 cm² area of degraded refractory), eliminating the need for widespread disassembly. This reduces repair time by up to 50% compared to traditional manual inspections.

- Avoid Unplanned Shutdowns:By identifying issues during routine operation (e.g., during scheduled maintenance windows), thermal imaging minimizes emergency repairs and keeps production on schedule.

- Detect Leaks and Emissions:Infrared cameras can identify gas leaks (e.g., CO, NOx) by visualizing temperature anomalies around seals or flues, helping manufacturers comply with emission regulations and prevent hazardous exposures.

- Ensure Insulation Integrity:Adequate furnace insulation reduces heat loss and lowers carbon emissions. Thermal imaging verifies that insulation materials (e.g., ceramic fiber) remain effective over time.

Infrared thermal imaging is a transformative tool for glass furnace management, offering proactive, data-driven insights that enhance safety, optimize energy use, and safeguard glass quality. By merging real-time thermal analytics with predictive maintenance, it minimizes the risks of catastrophic failures, reduces operational costs, and ensures the reliability of one of the most critical assets in glass production.