A vertical furnace body with continuous feeding is used to calcine limestone, so that the limestone is decomposed into quicklime CaO and carbon dioxide CO2 under high temperature conditions.

Several common problems in the production process of lime kilns include raw burning, overburning, upward or downward movement of the calcination zone, nodules, and kiln deviation.

The application of infrared thermal imaging in lime kilns has the following benefits:

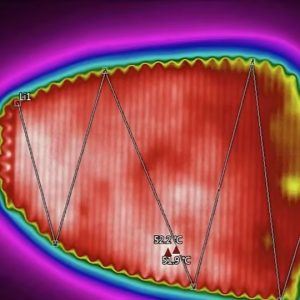

An infrared thermal imaging camera serves as the core device to monitor the surface temperature of lime kilns in real time, enabling operators to promptly grasp the temperature distribution both inside and outside the kiln. This capability, enhanced by a supplementary camera with infrared for detailed spot checks, helps prevent equipment damage and safety accidents while ensuring production continuity and stability.

By leveraging the high-resolution detection of this core camera, abnormal hot spots on the kiln surface can be identified, allowing early detection of lining damage or wear. A thermal image camera integrated into the system further analyzes temperature gradients to support data-driven decisions, facilitating planned shutdown maintenance, avoiding sudden failure-induced downtime, and enhancing equipment availability.

The thermal image camera plays a pivotal role in optimizing the combustion process by providing precise temperature feedback. Paired with the supplementary camera for real-time flame analysis, the system minimizes fuel waste, reduces energy consumption, and improves combustion efficiency—thereby ensuring the stability and safety of the production process.

Through continuous monitoring by the core camera, real-time adjustments to kiln temperature are enabled, guaranteeing the quality and stability of lime products while mitigating issues caused by temperature fluctuations. The thermal image camera further enhances this by capturing high-contrast thermal profiles for fine-grained control.

The system incorporates multiple safety measures, such as over-temperature alarms triggered by the core camera and abnormal pressure alerts. Operators can remotely access the system interface via the internet, using the supplementary camera’s feed for real-time visuals, to monitor production status and execute remote controls—effectively reducing on-site safety risks.

With remote monitoring facilitated by the thermal image camera, managers can assess production and equipment status in real time, enabling remote management and control that minimizes personnel involvement. This capability, supported by the core camera for automated data logging, helps enterprises reduce the risk of personnel injury.

By analyzing temperature data from the core camera and supplementary camera-enabled airflow sensors, the system accurately controls combustion parameters, ensures full fuel utilization, and optimizes ventilation. The thermal image camera consolidates these inputs to generate actionable insights, further enhancing production efficiency.