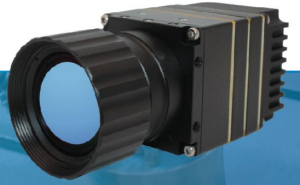

Pantograph Monitoring Infrared thermal imagers installed on electric locomotives are used to continuously observe the thermal status distribution on the pantograph surface in real time during train operation. As the pantograph assembly is exposed at the top of the EMU and subject to complex forces that can easily cause faults, the infrared thermal imager can capture multiple infrared thermal images per second. Combined with backend intelligent analysis algorithms, it can locate and diagnose pantograph anomalies, identify equipment defects by analyzing thermal images, and provide advance warnings for potential faults and overheating, ensuring safe and orderly railway transportation.

Catenary Monitoring Affected by mechanical tension, the overhead catenary suspension is prone to overheating and connection failures, which can cause the contact wire to extend, loosen, or even block the wire. Infrared thermal imagers can continuously collect temperature data for each measurement point on the catenary, including position, measured values, or operating status. In case of anomalies, the system automatically generates alarms to prompt staff to address equipment faults in a timely manner, eliminating potential hazards at an early stage.

Pantograph-Catenary Connection Point Detection Infrared thermal imaging equipment installed on the roof is used to detect the temperature at the connection between the pantograph and catenary, enabling real-time monitoring of catenary fault points. When arcing, hard spots, or other issues occur at the contact points during train movement, instantaneous high temperatures are generated. The thermal imager can record the high-temperature values and fault point locations, facilitating timely repairs by maintenance personnel.