Background

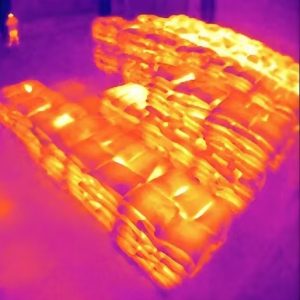

The blast furnace is an ironmaking equipment and the first process of steel smelting. Only after iron ore is smelted in the blast furnace can various pig iron blocks or molten iron for steelmaking be obtained.

The blast furnace production process is the process of smelting iron ore into pig iron at high temperature. Iron ore coke and slag flux (limestone) are loaded from the top of the furnace, and preheated air is blown in from the tuyere located at the bottom of the furnace along the furnace periphery. Under high temperature, the carbon in the coke (some blast furnaces also spray auxiliary fuels such as coal powder, heavy oil, and natural gas) reacts with the oxygen in the blown air to produce high temperature and reducing gases. These reducing gases heat the slowly descending charge during the rising process and reduce the iron oxides in the iron ore to metallic iron.

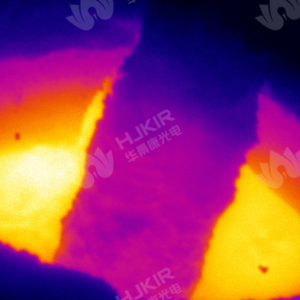

Blast furnace ironmaking is a relatively complex process, which requires blast furnace operators to easily understand the temperature distribution in the entire furnace before and after the charge distribution, the direction of the airflow, and the distribution of leaking pipes, collapsed materials, and material surface inclination, so as to carry out scientific and reasonable operation of the charge distribution. At the same time, the operating conditions of other equipment in the furnace can also be observed, such as: chute, cross temperature measurement, probe, etc.

Therefore, timely acquisition of information in the blast furnace during the smelting process will help blast furnace operators to better control the blast furnace, change from passive to active operation, avoid accidents, and enable the blast furnace to achieve the goals of safety, stable production, high production, low consumption and longevity, thereby achieving good social benefits and huge economic benefits.

Advantagies

infrared thermal imaging camera,camera with infrared,

Short-wave temperature measurement (ir camera for sale) has the following significant advantages, especially in the fields of industrial detection, remote sensing monitoring, high-temperature measurement, etc.:一. Fast response speed, suitable for dynamic measurement 二、Small environmental interference and high measurement accurac...

In an era where precision and efficiency define industrial success, forward-thinking kiln operators are revolutionizing their maintenance strategies. By harnessing the power of small infrared cameras, kiln cement, and kiln Portland cement, modern facilities are achieving unprecedented levels of performance and reliability. This artic...