Background description:

Background description:Electricity is an energy source that uses electrical energy as a driving force. It is an electricity production and consumption system consisting of power generation, transmission, transformation, distribution and power consumption. It converts primary energy in nature into electricity through mechanical - energy devices, and then supplies electricity to various users through transmission, transformation and distribution. The main ways to generate electricity are: thermal power generation (combustible materials such as coal), solar power generation, large - capacity wind power generation technology, nuclear power generation, hydrogen power generation, hydropower generation, etc.

Early fault detection: During the transforming process, electrical equipment may generate abnormal heat due to poor contact, overload, aging and other reasons. Infrared thermal reasoning technology can detect these potential faults in time by detecting the temperature distribution on the surface of the equipment. Faults are detected in their budding state, thereby avoiding further development of faults and reducing equipment damage and power outage accidents. For example, the winding and winding of the transformer, as well as the contacts of the high-voltage switch and the connection points of For example, the winding and winding of the transformer, as well as the contacts of the high-voltage switch and the connection points of the busbar are all key parts that are prone to heat. Infrared thermal imaging can monitor these parts in real time and detect abnormal temperature rises in time. time.

Non-contact detection: Infrared thermal imaging is a non-contact detection method that does not require direct contact with the equipment, which is very important for the detection of high voltage, energized equipment. In a high-voltage environment such as a substation, the staff can detect the equipment at a safe distance, avoiding the risk of electric shock due to contact with the equipment, and safeguarding the personal safety of the staff. At the same time, non-contact detection will not interfere with the normal operation of the equipment, without power outages can be detected, greatly improving the flexibility and convenience of detection.

Comprehensive monitoring: infrared thermal imaging technology can carry out comprehensive temperature monitoring of various equipment in the substation, such as transformers, circuit breakers, disconnect switches, transformers, capacitors, cables and so on. By scanning and analyzing the temperature distribution of the entire substation equipment, abnormalities in the equipment can be quickly found and timely measures can be taken to deal with them. Moreover, the thermal imager can monitor multiple devices at the same time, which improves the monitoring efficiency and reduces the workload of manual inspection.

PSGMT490 dual-spectrum head is a dual-spectrum T-type high-speed head, equipped with thermal cameras and high-definition visible light, small size, light weight and wide monitoring range. Thermal imaging cameras can be installed on mobile robots, and is widely used in substation, power distribution room, factory inspection and other scenarios.

Advantage:

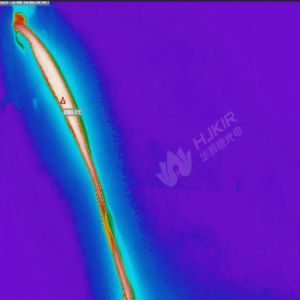

HJKIR developed a new type of continuous temperature measurement system for molten iron, which can directly measure the temperature of the iron flow at the taphole during tapping and more directly and accurately represent the state and change process of the physical heat of the furnace. At the same time, it has the outstanding characteristics of...

Infrared thermal imager solution for metallurgy, application sence is Ladle, hjk system establish a surface temperature database for each ladle use cycle ans 360° all-round temperature detection of the package, and 3D schematic diagram shows the temperature field distribution of the package.

infrared thermal imaging technology improved detection efficiency, real-time monitoring, preventive maintenance, safety improvement and economic improvement