Infrared thermal imaging cameras offer significant advantages for inspecting heating furnaces, particularly in ensuring operational safety, optimizing energy efficiency, and maintaining equipment reliability. Here are the key benefits:

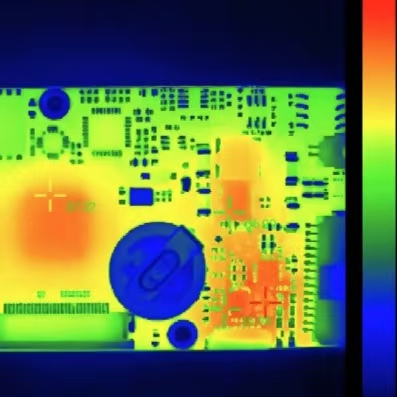

- Uniform Heating Verification:

Heating furnaces (e.g., for metal annealing, glass melting, or industrial drying) require precise temperature uniformity. Infrared imaging quickly identifies hotspots or cold zones on the furnace surface or interior (e.g., uneven heat distribution due to faulty heating elements or blocked airflow).

Example: In a steel heat-treatment furnace, thermal imaging detected a 50°C temperature deviation in the upper chamber, allowing timely adjustment of burner positions to prevent product hardness inconsistencies.

- Dynamic Process Optimization:

By visualizing temperature gradients in real time, operators can fine-tune heating parameters (e.g., gas flow, power input) to match process requirements, reducing overheating or underheating and improving product quality consistency.

- Heating Element Faults:

Burners, resistive coils, or infrared emitters may degrade over time, leading to localized cooling. Thermal imaging spots underperforming elements (e.g., a dark blue area indicating a failed coil in a red-hot furnace), enabling proactive replacement before complete failure causes downtime.

- Refractory Material Damage:

Cracks or erosion in furnace linings (e.g., ceramic or brick refractories) increase heat loss and risk structural failure. Infrared imaging reveals temperature leaks through damaged linings (e.g., a sudden spike in surface temperature), providing 3–6 months’ advance warning compared to traditional visual inspections.

Impact: Early detection can save $10,000–$100,000 in repair costs by avoiding catastrophic lining collapse and furnace shutdowns.

- Heat Loss Identification:

Leaks in insulation, gaps in furnace doors, or damaged seals cause significant heat escape. Thermal imaging maps surface temperatures to pinpoint inefficiencies (e.g., a 100°C hot spot on a poorly sealed door), guiding targeted repairs.

Data: A ceramics factory reduced natural gas consumption by 12% after optimizing furnace insulation based on thermal imaging data, saving $50,000 annually.

- Combustion Efficiency Analysis:

In gas-fired furnaces, improper air-fuel ratios lead to incomplete combustion and wasted energy. Infrared imaging, combined with gas analysis, evaluates flame temperature and uniformity (e.g., a weak, cool flame indicating excess air), allowing adjustments to minimize fuel waste and emissions.

- Operator Protection:

Furnace environments often exceed 1,000°C, with risks of burns, explosions, or toxic gas leaks. Thermal imaging enables safe remote inspection (from 10+ meters away), eliminating the need for personnel to enter high-risk zones during operation.

- Emergency Leak Detection:

In chemical or petrochemical furnaces, invisible gas leaks (e.g., methane, CO) can be fatal. Infrared cameras with gas-specific filters (e.g., for SF6 or VOCs) visualize leaks as thermal anomalies, enabling immediate shutdowns to prevent accidents.

- Trend Analysis for Proactive Repairs:

Thermal imaging systems store historical data, allowing trend analysis (e.g., a gradual 5°C/year increase in furnace wall temperature, indicating lining degradation). This shifts maintenance from reactive (“break-fix”) to predictive, reducing unplanned downtime by 30–50%.

- Reduced Inspection Costs:

Traditional methods (e.g., thermocouple spot checks, shutdown visual inspections) are time-consuming and incomplete. Infrared imaging provides full-surface scans in minutes, cutting inspection time by 70% and lowering labor costs.

- Regulatory Compliance:

Industries like aerospace, automotive, and food processing require strict temperature documentation for quality control. Thermal imaging generates traceable temperature reports and images, ensuring compliance with ISO, ASTM, or FDA standards.

- Product Defect Prevention:

Inconsistent furnace temperatures cause product defects (e.g., warping in metal casting, delamination in composite curing). Real-time thermal monitoring ensures uniform processing, reducing scrap rates by up to 20%.

Infrared thermal imaging transforms heating furnace inspection from a reactive, labor-intensive process into a proactive, data-driven strategy. By combining real-time temperature insights, safety enhancements, and energy savings, it delivers a strong ROI for industries reliant on precise, high-temperature operations. Whether used in steel mills, glass factories, or chemical plants, thermal imaging is essential for maximizing uptime, minimizing risks, and optimizing productivity.

-1-1024x640.png)