Background description:

Background description:Boiler is the key equipment in industrial production and heating system, and its internal combustion process will produce high temperature and high pressure environment. In the process of boiler operation, the temperature condition of the furnace wall, pipeline, burner and other components is directly related to the safety and efficiency of the boiler. The traditional boiler monitoring method mainly relies on the temperature sensor installed inside the boiler to measure the temperature of several key positions, but this way can not fully reflect the overall temperature distribution of the boiler. Infrared boiler products Use infrared thermal imaging technology to monitor the external surface of the boiler for a large area, non-contact temperature.

Solution:

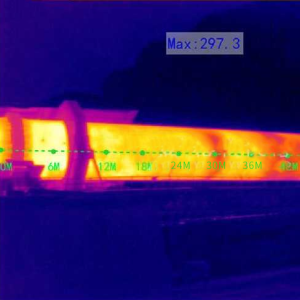

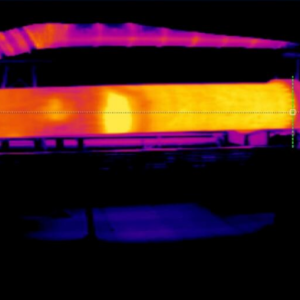

The high temperature resistant endoscope infrared thermal imaging thermometer is used to monitor the temperature of the water wall in real time by inserting the lens into the boiler, remotely view the status of the water wall, and actively make corrections according to the detection information to avoid abnormal situations such as boiler damage.

Advantages:

| key technical indexes | ||

| Use ambient temperature | Furnace temperature | ≦ 1600℃ |

| navar | ≦ 70℃ | |

| Automatic exit device | Automatic exit protection function | When power failure, gas stoppage, overheating and under voltage, the probe can automatically withdraw from the furnace |

| Exit device travel | 100-6 00mm, customizable according to the thickness of the furnace | |

| Manual insertion and exit function | have | |

| control device | Integrated touch screen system | 8 relays, 4 transistors |

| Control of three places | It can realize on-site control and operation on mobile phone | |

| Infrared thermal imaging | Type of detector | Non-cooled focal plane detector |

| resolution ratio | 384×288 | |

| Lens focal length | 3.3mm | |

| angle of field | 98°× 76° | |

| Lens type | High temperature resistant pinhole lens | |

| Temperature measurement range | 50℃~1600℃ | |

| temperature measurement accuracy | ± 2℃ or 2% | |

| networking protocol | Support ONVIF/RTSP/FTP/PPPOE/DHCP/DDNS/NTP/UPnP/TCP | |

| Visible light camera | resolution ratio | 2 to 4 megapixels are optional |

| focal distance | 4.7~94mm 20 times | |

| dynamic range | 120db | |

| ICR changing-over | support | |

| minimal illumination | Color 0.05lux@F1.6 | |

| video compression | H.264/H.265 | |

| Vortex cold tube (optional) | When the inlet of compressed air is greater than 0.35MP, the temperature difference of compressed air outlet is 23 degrees | |

| Power supply requirements | service voltage | AC220V±10% |

| Power supply frequency | 50Hz | |

| Installation distance | The maximum distance from the equipment to the on-site control box is 1.5 meters | |

HJKIR Infrared power plant products solutions offers PSGMT490 dual-spectrum head infrared camera with 255 preset bits. Widely used in substation, power distribution room, factory inspection and other scenarios. Offers self-test function, manual control of multi-level speed adjustable functions.

When working with kilns, proper cooling and maintenance are crucial for safety and efficiency. One critical step is kiln cooling and unloading, often referred to as "kiln unloading" or "kiln discharge." In this process, monitoring temperature and sealing any gaps are key to preventing heat loss and structural damage. Here’s how small...

In today's rapidly evolving industrial landscape, kiln operators face increasing pressure to maximize uptime while minimizing costs. This paradigm shift has given rise to a new era of predictive maintenance powered by three game-changing technologies: small infrared cameras, kiln cement, and kiln Portland cement. Let's examine how th...