Handheld infrared thermal imaging thermometer consists of intelligent operation terminal, high-resolution thermal heat camera sensor, high-definition visible light sensor and image fusion localization system, etc. It adopts dual-spectrum automatic fusion interweaving localization technology and relies on a cloud/server-side data management system, enabling automatic management and integration of the intelligent system for equipment ledger, inspection tasks, and inspection data. As a cheap thermal camera, it serves as an intelligent system integrating image acquisition, data processing, and fault diagnosis, functioning not only as a terminal inspection instrument but also as a basis for building industrial intelligent inspection systems via digitized templates and intelligent target recognition. Optional thermal video camera price configurations support extended capabilities like real-time recording, enhancing diagnostic accuracy for complex scenarios while maintaining system scalability.

Product technical indicators

| Technical Parameters | Version | |

| H43E13 | H42E3 | |

| Spatial resolution (IFOV) | 1.30 mrad | 3.0mrad |

| angle of field (FOV) | 28.7°×21.6° | 42°×32° |

| camera lens | 13 mm | 3 mm |

| temperature measurement accuracy | ±2℃ or ±2% of the reading (take the maximum value) | |

| Temperature measurement range | -20℃~ 600℃ | -20℃~ 600℃ |

| heat sensitivity | 0.05℃@25℃ | |

| operating distance | ≥0. 1 m | |

| resolution ratio | 384×288 pixels | 256× 192 pixels |

| Super pixel technology | Enhance to 768x576pixels | 512× 384 pixels |

| Working band | 7.5-14um | |

| Visible light pixels | 15 megapixels | |

| Operate the screen | 5. 5 inches | |

| Naming thermal images | Scan the QR code or enter the name manually | |

| data interface | USB-C (wired), Wifi/Bluetooth (wireless) | |

| GPS fixed position | Automatically add GPS location information to each image | |

| Display mode | Separate infrared thermal imaging, separate visible light, dual spectrum automatic fusion | |

| Over temperature alarm | Custom temperature threshold, over-temperature color alarm and sound alarm | |

| Historical data curve | Based on big data analysis, the historical temperature curve and temperature rise curve are automatically generated | |

| Converged technology | S inga rd Dedicated dual-spectrum automatic fusion technology (VL/IR Fusion) | |

| duration of flight | More than 8 hours | |

| working temperature | -10℃~50℃(14℉~122℉) | |

| Storage temperature | -20°C ~+60°C (-4°F ~ +140°F) | |

| Host weight | 50 0g | 30 0g |

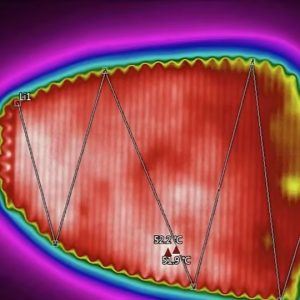

The high temperature resistant endoscope infrared thermal imaging thermometer is used to monitor the temperature of the water wall in real time by inserting the lens into the boiler, remotely view the status of the water wall, and actively make corrections according to the detection information to avoid abnormal situations such as boiler damage.

Infrared cameras have become a crucial tool in the automotive industry,infrared devices play a crucial role in monitoring and analyzing heating wires across various industries

infrared thermal imaging technology improved detection efficiency, real-time monitoring, preventive maintenance, safety improvement and economic improvement