Software

Standard software

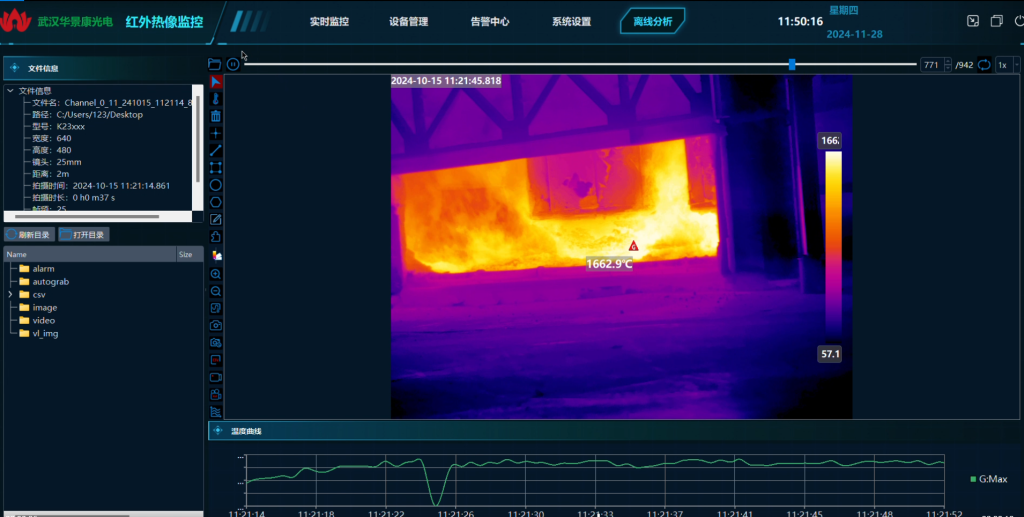

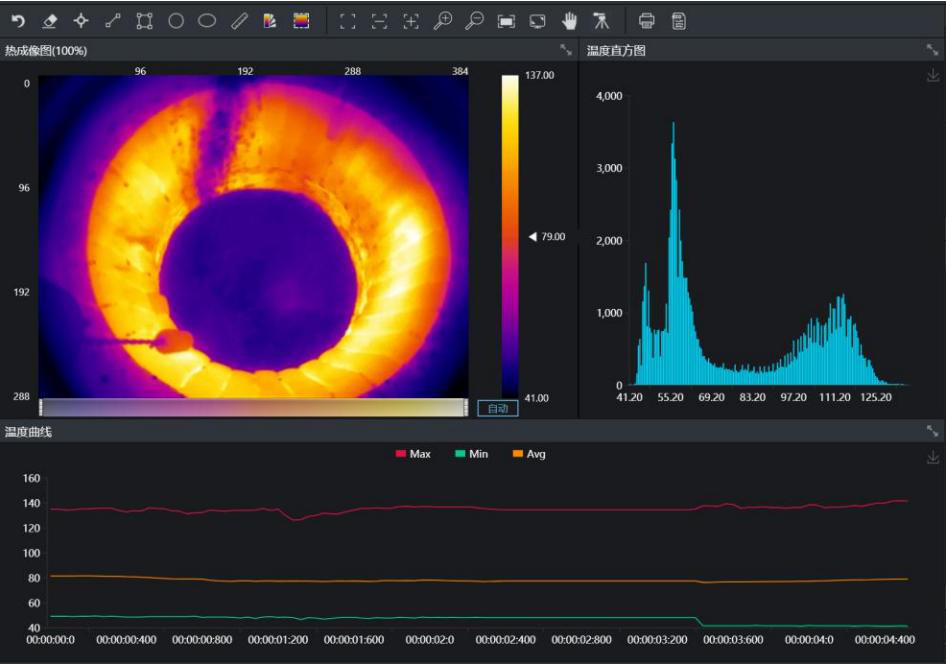

InfraredStudio(lRS)

- Data capture: Thermal imaging image data can be collected regularly for later analysis

- Custom alarm thresholds and levels: The system can define multiple different alarm thresholds and levels to assist staff in assessing the urgency and development trend of hidden dangers

- Real-time video display

- Temperature tracking

- High temperature trigger shooting and alarm

Customized software

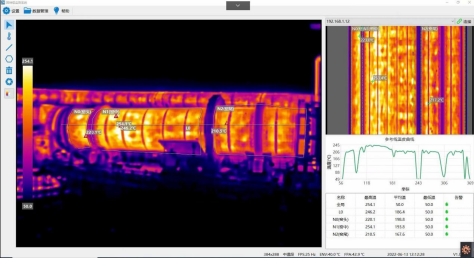

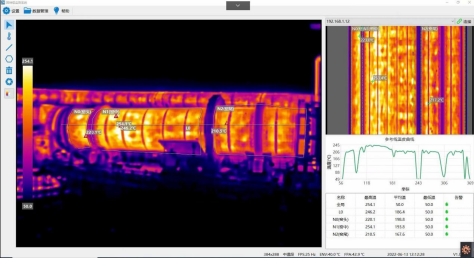

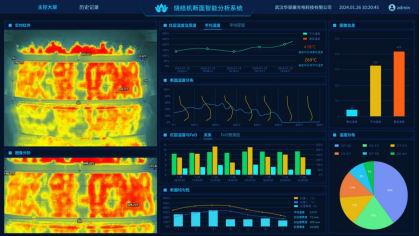

I. Rotary kiln shell

- Real-time video display

- Temperature tracking

- Data capture

- High temperature trigger shooting and alarm

- Automatic splicing of kiln shell infrared thermal images

- Fault self-diagnosis: When the terminal device fails, the system automatically alarms

- Custom alarm thresholds and levels

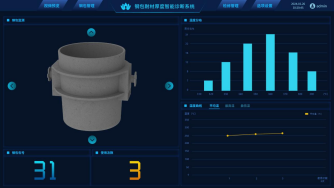

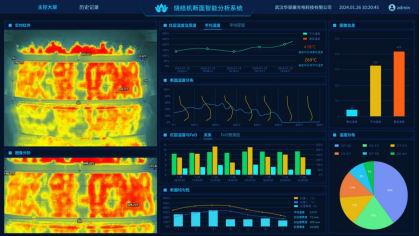

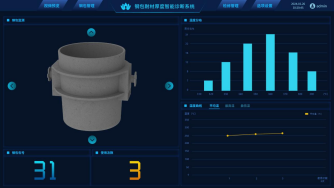

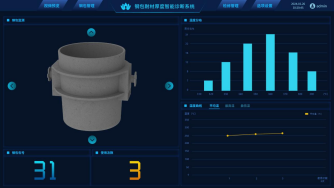

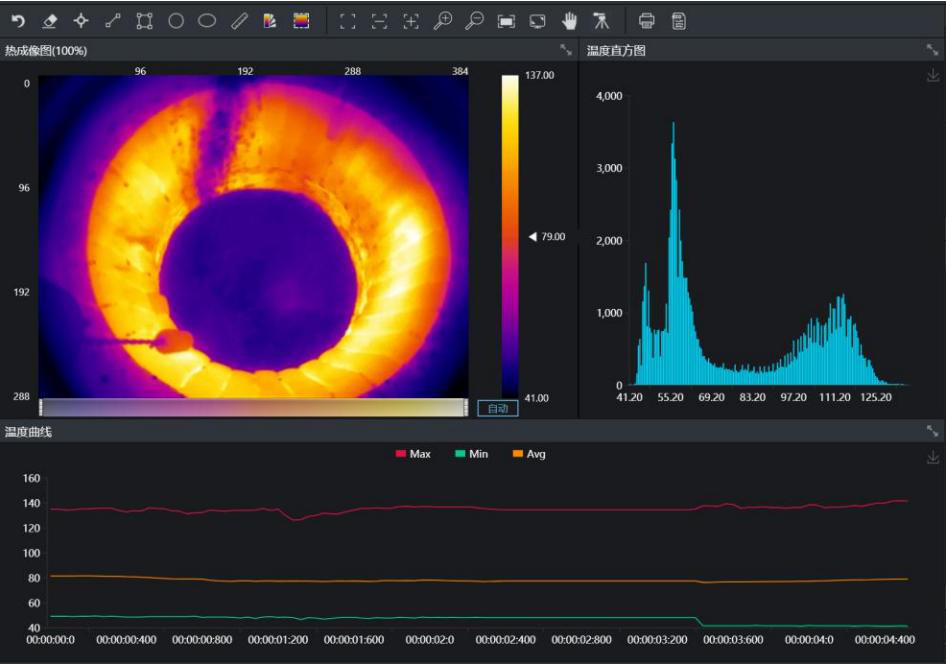

II. Ladle

- All-weather passive thermal imaging function

- Self-developed temperature measurement and correction algorithm

- Strong environmental adaptability

- Automatic identification of package number

- 360° all-round temperature detection of package

- Automatic positioning and warning of 1 square decimeter high temperature area

- Establish a corresponding model between the refractory material of the package and the surface temperature of the package

- Establish a surface temperature database for each ladle during its use cycle

- Open interface, provide SDK development package, can be connected with DCS, PLC and other systems

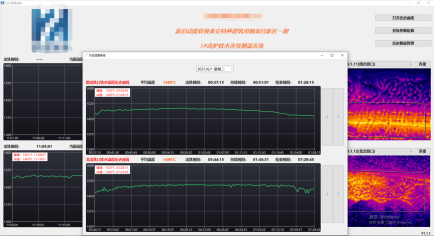

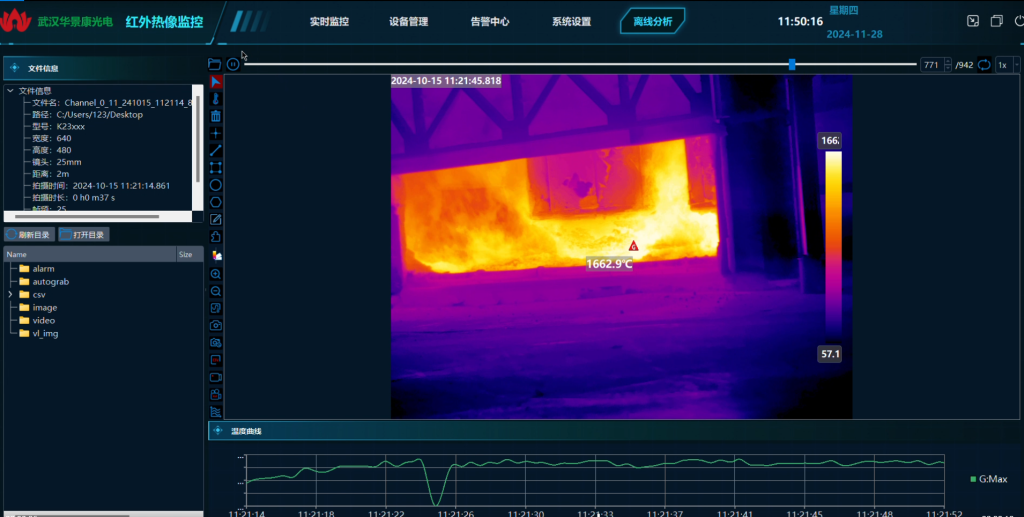

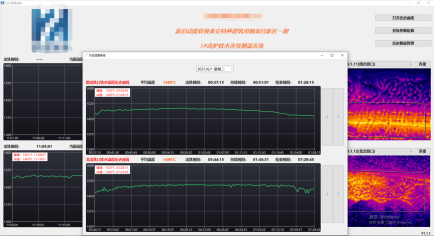

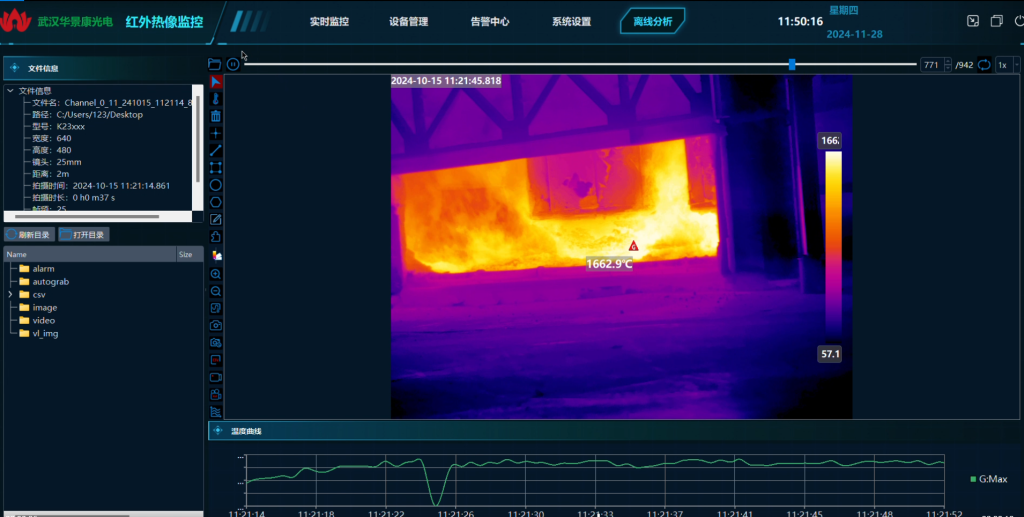

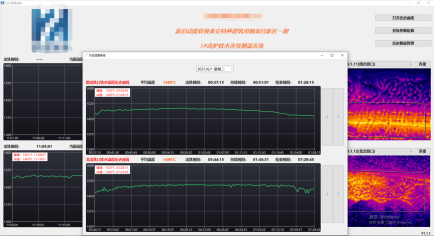

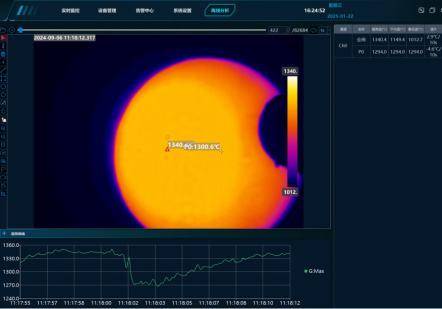

III. Molten iron

1.Real-time display of molten iron temperature

2.Automatically record the start time, end time and duration of tapping

3.Real-time video clearly displays the tapping situation

4.Prompts for abnormal temperatures

5.Real-time automatic detection of tapping status at each tapping point

6.Automatically save current temperature and average temperature

7.Query historical data and monitoring interface

8.Can overcome the interference of factors such as dust and high temperature on site, and measure accurate tapping point molten iron flow temperature field distribution, including tapping point molten iron temperature and tapping point slag temperature

9.Can be connected to the LED screen through ModBus protocol, analog output, etc. to display temperature

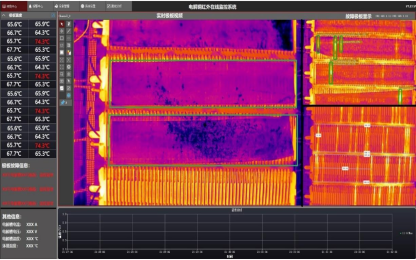

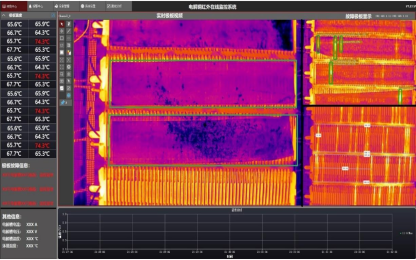

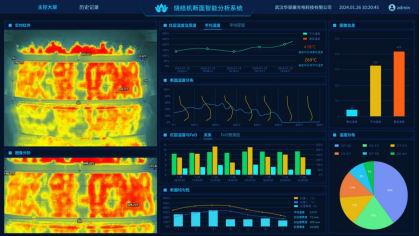

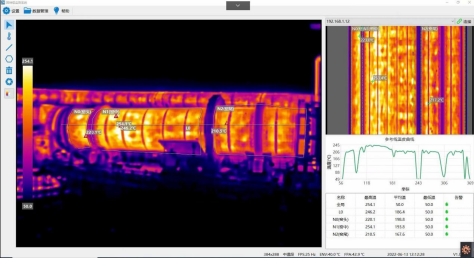

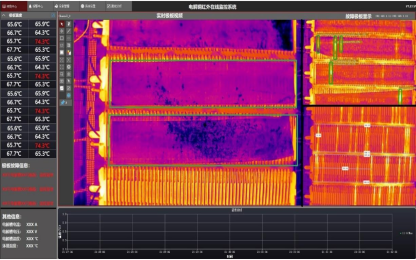

IV. Non-ferrous metal electrolysis cells

1.Real-time video display area

2.Fault video display area

3.Fault plate information display area

4.Plate temperature display area

5.Other information: Displays the slot temperature, slot pressure, slot current, workshop environment temperature and humidity and other information input to the system

6.Curve display area: Various temperature curves can be displayed according to user settings, such as the highest point temperature curve in the real-time video, the temperature curve of the set special monitoring point, the average temperature curve in the real-time video, etc

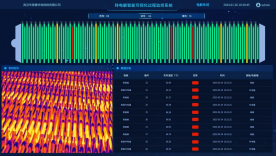

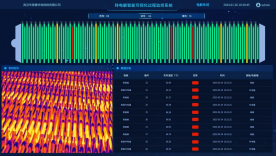

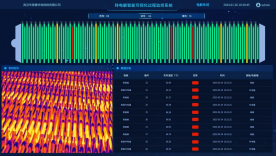

V. Zinc Electrowinning

- Electrolytic cell layout: It can fully display the status of the plates in all electrolytic cells in the workshop. Normal plates are displayed in green, and short-circuited plates are displayed in red and yellow

- Alarm disposal list

- Infrared real-time video display area: It mainly displays the real-time infrared video of the electrolytic cell area currently being inspected

- Data analysis area

- Alarm information statistics

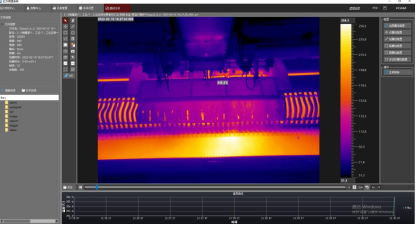

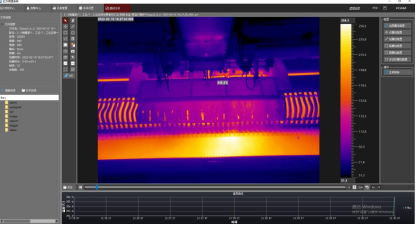

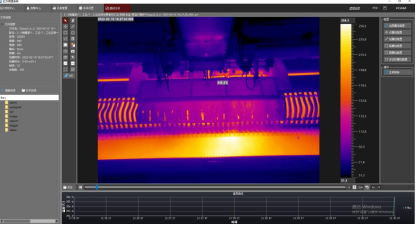

VI. Sintering machine tail

- Real-time video display

- Temperature curve display: Real-time display of the change trend of the cross-section temperature of the sintering machine under different sintering conditions over time

- Data analysis: According to the sintering process knowledge, analyze the cross-section feature pictures, extract the process data related to the production quality status, save and display it on the system interface

- Temperature compensation

- Fault self-diagnosis

- Data management

- Support multi-platform open API interface docking

- User authority management

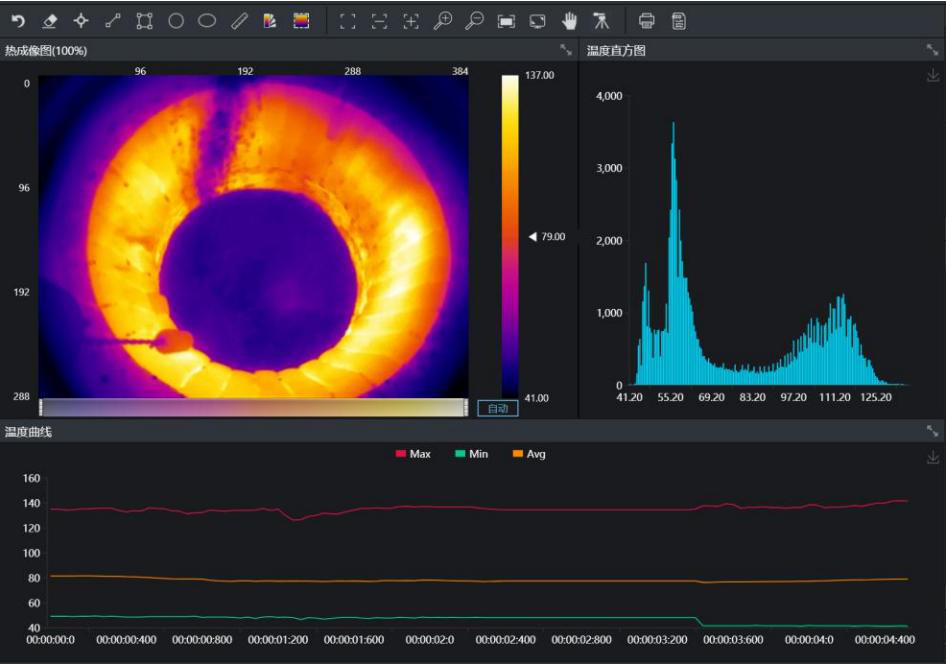

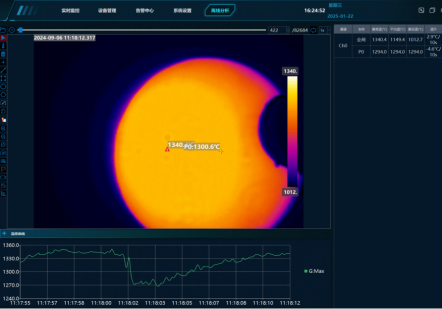

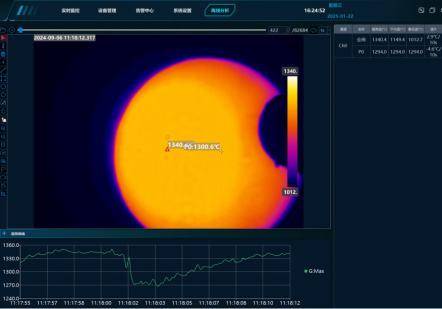

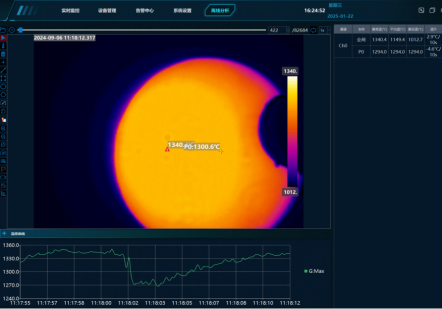

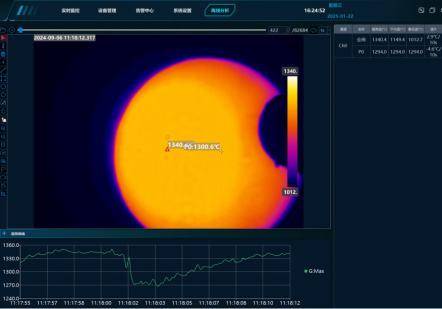

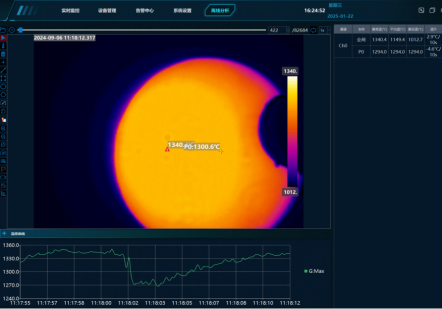

VII. Blast furnace charge surface

- Real-time video display of the material surface in the furnace

- Real-time display of the full radiation thermal map of the material surface in the furnace. The temperature at any position in the infrared thermal map can be viewed. The temperature display frequency can be set. The default setting is the same as the cycle of one circle of the chute. The temperature is collected when the chute rotates to the opposite side of the system installation

- Temperature tracking: Automatically display the highest and lowest temperature points, highlight the specified temperature range; according to the habits of the blast furnace operator, the effect of "cross temperature measurement" can be achieved

- Data capture

- High temperature trigger shooting and alarm

- Fault self-diagnosis

- Custom alarm threshold and level

- Data recording

VIII. P-S Converter

- All-weather passive thermal imaging function

- Self-developed temperature measurement and correction algorithm

- Strong environmental adaptability

- All-round temperature detection of furnace wall, comprehensive display of furnace temperature field distribution

- Automatic positioning and early warning of 1 square decimeter high temperature area

- Establish a furnace wall surface temperature database

- Build a corresponding model of refractory material thickness and furnace surface temperature

- Open interface, provide SDK development package, can be connected with DCS, PLC and other systems

IX. Anode furnace

- With all-weather passive thermal imaging function

- Adopt self-developed temperature measurement and correction algorithm

- Strong environmental adaptability, can be used in harsh environments such as high temperature and high dust

- High temperature solution temperature monitoring in the furnace

- 360° all-round temperature detection of the furnace wall

- Automatic positioning and warning in high temperature areas

- Open interface, provide SDK development package, can be connected with DCS, PLC and other systems

X. Continuous casting billet

- Real-time display of full radiation heat map and high-definition visible light video

- Up to 32 temperature measurement objects can be drawn, such as points, lines, circles, rectangles, polygons

- 3D temperature field and isotherm display, temperature distribution is more intuitive

- Up to 12 color palettes, suitable for use in more application scenarios

- Highest temperature, lowest temperature, average temperature multi-point temperature tracking

- Support up to 32 devices online at the same time; automatic reconnection when disconnected

- Adaptive display resolution, support vertical screen display

XI. Roller centrifugal casting

- With all-weather passive thermal imaging function

- Real-time measurement of the temperature of the high-speed rotating rollers during the casting process of the roller centrifuge

- The temperature data detected by the system is associated with the roller centrifuge stop system, and the centrifuge stop time can be controlled according to the temperature

- Adopt self-developed temperature measurement and correction algorithm

- Strong environmental adaptability

- High protection level

- Adopt high frame rate design

- Temperature data can be connected to LED screen and PLC

- Temperature measurement accuracy is better than ±1%

- Open interface