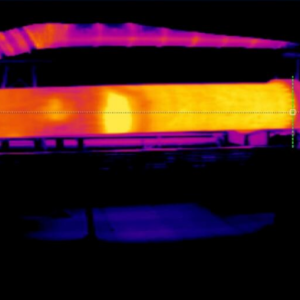

Infrared thermal imaging monitors the surface temperature distribution and solidification state of the continuous casting billet, warns of defects such as cracks, shrinkage holes, and abnormal cooling in the secondary cooling zone, and provides real-time data support for continuous casting process optimization and billet quality control.

HIRDA-LZ continuous casting billet IR thermal imaging camera intelligent monitoring system is an infrared thermal imaging product specially used for continuous casting billet temperature monitoring. The system is mainly composed of infrared cam movement, infrared lens, air-cooled metal protective cover, thermal imager control cabinet, image algorithm server and client software. The system adopts full-amplitude radiation temperature measurement technology, which can simultaneously obtain multipoint temperature value; temperature measurement range up to 2500℃; self-developed temperature measurement algorithm with high temperature measurement accuracy; metal shield design, IP66 protection grade; the system software can realize the functions of target infrared heat map display, thermal data collection, storage and analysis, alarm at high and low temperature, positioning and temperature tracking. This product has been widely used in iron and steel metallurgy, non-ferrous metals, electric power, cement, glass and many other industries temperature monitoring.

Operating temperature range is wide, can work at-20 ℃ ~ + 60 ℃ ambient temperature;

Infra red camera has high protection level, the highest protection level can reach IP66;

Full-screen real-time temperature measurement, wide coverage range;

Without relying on the system platform, it can directly log in to the web page to access the image and configuration, and can directly output the alarm signal to the PLC or the alarm;

Support the onvif protocol, can access to the mainstream NVR;

Temperature data can be connected to the LED screen and the PLC;

Electric / autofocus, at any time through the software to focus operation;

Temperature measurement range can be customized, the maximum support-20℃ to 2500℃;

The temperature measurement accuracy is better than ± 2℃ or ± 2%;

Support the modbus protocol and can dock with the DCS system for temperature data transmission.

infrared thermal imaging technology Real-time monitoring and fault location efficiency Safety assurance

infrared thermal imaging technology improved detection efficiency, real-time monitoring, preventive maintenance, safety improvement and economic improvement

In today's rapidly evolving industrial landscape, kiln operators face increasing pressure to maximize uptime while minimizing costs. This paradigm shift has given rise to a new era of predictive maintenance powered by three game-changing technologies: small infrared cameras, kiln cement, and kiln Portland cement. Let's examine how th...

infrared thermal imaging Real-time temperature monitoring and fault detection Energy saving optimization Safety monitoring