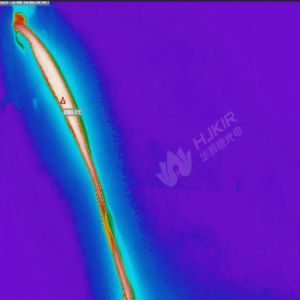

Blast furnace charge surface management is a key link to ensure uniform charge distribution, smooth gas flow and stable smelting process. Its core goal is to control the order of charge loading, charge angle and charge flow speed to form a reasonable charge surface shape (such as ring, spiral, etc.), thereby optimizing the gas distribution in the furnace and improving the iron ore reduction efficiency and pig iron quality.

HIRDA-BF blast furnace charge surface infrared thermal imaging online temperature detection and analysis system is a special system used to detect the temperature distribution of the charge surface in the blast furnace. The system consists of infrared thermal imaging core, high temperature resistant infrared thermal imaging lens, automatic retraction protection device, furnace installation kit, air filtration system and field equipment box, algorithm server and intelligent temperature measurement software.

The high-temperature resistant thermal infrared camera lens is installed in a retractable metal protective cover. The high-temperature resistant thermal imaging cameras lens is directly extended into the furnace through the retractable device. The infrared thermal imaging core stays outside the furnace to realize continuous real-time monitoring of the working status of the furnace.

The protective cover is cooled by compressed cooling air to make the infrared lens work at a more suitable temperature; at the same time, the lens is purged to prevent the dust in the furnace from adhering to the lens protection window; the system has a built-in high-temperature protection circuit. Once the cooling gas or cooling water circulation is abnormal, the lens will be retracted to prevent damage by the high temperature in the furnace.

Thermal heat camera has the characteristics of high temperature resistance, corrosion resistance and maintenance-free. It can display various complex working conditions inside the blast furnace in real time. When the camera probe purges compressed air normally, it is suitable for various positive pressure kilns.

◆With all-weather passive infrared temperature measurement function, real-time display of the temperature distribution of the material surface in the furnace

◆Adopt self-developed temperature measurement and correction algorithm to achieve accurate temperature measurement

◆Fully sealed to ensure that blast furnace gas does not leak

◆Ultra-large viewing angle, diagonal viewing angle can reach 120°

◆Spiral air curtain design, no dust accumulation on the lens

◆Overall stainless steel material, corrosion and temperature resistance

◆Automatic exit protection device, exit fault indication

◆Pneumatic/electric transmission mechanism

◆High temperature resistant optical pinhole lens, with dust-proof high temperature lens

◆Automatic exit from the furnace in case of over-temperature, under-voltage, and power failure

◆Support onvif protocol, can be connected to mainstream NVR

◆Not dependent on the system platform, can directly log in to the ip on the web page to access images and configurations, can directly output alarm signals to PLC or alarm

Infrared thermal imaging thermometer solution monitoring continuous casting process non-contact infrared measurement detection technology, HJK infrared thermal imager temperature range work in -20℃~+60℃, temperature measurement range from -20℃ to 2500℃ and with High protection level, can reach IP66, convient modes like optional Electric/automati...

HJKIR developed a new type of continuous temperature measurement system for molten iron, which can directly measure the temperature of the iron flow at the taphole during tapping and more directly and accurately represent the state and change process of the physical heat of the furnace. At the same time, it has the outstanding characteristics of...

LASER Photonics China 2025: A new chapter of optoelectronic technology innovation and global cooperation From March 11 to 13, 2025, the most influential event in Asia's optoelectronics industry, LASER Photonics China, will be held in Shanghai New International Expo Center. As the flagship exhibition in China's laser, optics and optoe...