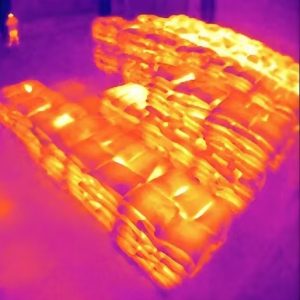

Ladles and iron ladles are key containers for transporting and storing liquid metal (molten steel, molten iron), and are widely used in core processes such as ironmaking, steelmaking, refining and continuous casting. Infrared thermal imaging can monitor the temperature distribution of the ladle's refractory layer, warn of lining wear and local overheating, and assist in ladle life management and safe and efficient operation of the steelmaking process.

HIRDA-L steel ladle intelligent diagnosis and analysis system is a high-tech system specially used to detect the temperature of steel ladle shell and conduct intelligent analysis. The system consists of high-temperature IR thermal camera, high-definition visible light camera, electric control box, algorithm server and client management software. It centrally monitors and manages the equipment on the operation site, and realizes data collection, analysis, high temperature point positioning, automatic alarm and ladle number recognition through digital transmission network.

1. IR video camera with all-weather passive thermal imaging function;

2. Adopt self-developed temperature measurement and correction algorithm to achieve accurate temperature measurement;

3. Strong environmental adaptability, can be used in harsh environments such as high temperature and high dust;

4. Automatic identification of ladle numbers and intelligent association of temperature data;

5. 360° all-round temperature detection of the ladle, 3D schematic diagram showing the temperature distribution of the ladle;

6. 1 square decimeter high temperature area automatic positioning warning;

7. Establish the corresponding model between the refractory material of the ladle and the surface temperature of the ladle;

8. I cam establish a surface temperature database for each ladle life cycle;

9. Open interface, providing SDK development kit, can be connected with DCS, PLC and other systems.

Blast furnace charge surface management is a key link to ensure uniform charge distribution, smooth gas flow and stable smelting process. Its core goal is to control the order of charge loading, charge angle and charge flow speed to form a reasonable charge surface shape (such as ring, spiral, etc.), thereby optimizing the gas distribu...

infrared thermal imaging camera,camera with infrared,

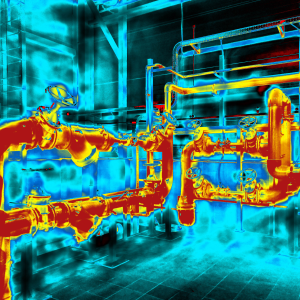

infrared thermal imaging technology improved detection efficiency, real-time monitoring, preventive maintenance, safety improvement and economic improvement

Invisible Dangers Thermal Cameras Reveal:✔ Gas leaks (shows as "cold clouds")✔ Tank leaks (wet areas look different)✔ Pump failures (abnormal heat patterns) Why Workers Love These Tools: Thermal imaging small cameras fit in tool belts No need to shut down equipment Takes 1/10th the time of old inspection methods Case Study:A refi...