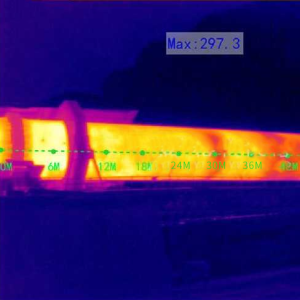

The PS converter is located after the copper concentrate is smelted and before the crude copper is refined in the pyrometallurgical copper smelting process of the copper plant. Infrared thermal imaging achieves safety protection, efficiency improvement, consumption reduction and precise temperature control by real-time monitoring of the PS converter furnace temperature distribution, early warning of equipment failures and optimization of process parameters.

HIRDA-PS type The PS converter infrared thermal imaging intelligent monitoring system is a system specially designed for high temperature metal smelting. The furnace temperature monitoring system consists of a high-temperature infrared in thermometer, an electric control box, an algorithm server and a customer Centrally monitor and manage the equipment on the job site and transmit it through a digital transmission network Realize PS Collection, analysis, and location of high-temperature points of converter wall temperature. Automatic alarm and other functions.

Ir video camera has all-weather passive thermal imaging function;

Use self-developed temperature measurement and correction algorithm to achieve accurate temperature measurement;

Infrarood camera has strong environmental adaptability, can be used in harsh environments such as high temperature and high dust;

Full range temperature detection of furnace wall to fully display the temperature field distribution of furnace body;

Automatic positioning and warning of high temperature areas in square decimeters;

Establish a furnace wall surface temperature database;

Build a corresponding model between refractory material thickness and furnace surface temperature;

Open interface, providing SDK Development kit, available with DCS、 PLC Waiting for system connection.

When working with kilns, proper cooling and maintenance are crucial for safety and efficiency. One critical step is kiln cooling and unloading, often referred to as "kiln unloading" or "kiln discharge." In this process, monitoring temperature and sealing any gaps are key to preventing heat loss and structural damage. Here’s how small...

Critical Areas to Monitor: Furnace walls (hot spots = thinning) Conveyor bearings (heat = failing soon) Ladles (uneven heating risks cracks) Why This Beats Old Methods:Old way:✖ Shut down for inspections✖ Guess based on experience New way with thermal imaging small tech:✓ Scan during operation✓ See exact trouble spots Cost-Savin...

infrared thermal imaging technology Real-time monitoring and fault location efficiency Safety assurance

LASER Photonics China 2025: A new chapter of optoelectronic technology innovation and global cooperation From March 11 to 13, 2025, the most influential event in Asia's optoelectronics industry, LASER Photonics China, will be held in Shanghai New International Expo Center. As the flagship exhibition in China's laser, optics and optoe...