Critical Areas to Monitor:

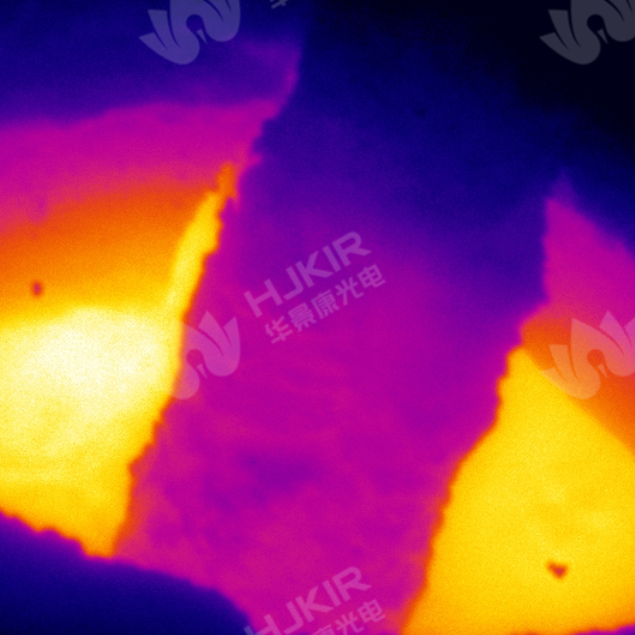

Furnace walls (hot spots = thinning)

Conveyor bearings (heat = failing soon)

Ladles (uneven heating risks cracks)

Why This Beats Old Methods:

Old way:

✖ Shut down for inspections

✖ Guess based on experience

New way with thermal imaging small tech:

✓ Scan during operation

✓ See exact trouble spots

Cost-Saving Proof:

A mill using infrared cameras thermal imaging reduced bearing failures by 70% in one year.

Smart Buying Advice:

When comparing infrared imaging camera price, ensure it can handle:

→ High dust environments

→ Vibrations from heavy machinery

→ Extreme temperatures

Short-wave temperature measurement (ir camera for sale) has the following significant advantages, especially in the fields of industrial detection, remote sensing monitoring, high-temperature measurement, etc.:一. Fast response speed, suitable for dynamic measurement 二、Small environmental interference and high measurement accurac...

Read More

3 Big Benefits: Spot furnace problems before they ruin batches Save energy by finding heat leaks Improve quality with even heating Real-World Example:A cement plant using infrared cameras thermal imaging found a hidden hot spot that could have caused a 3-week shutdown. The fix took 2 days. How It Works in Practice: Scan electrolytic...

Read More