Background:

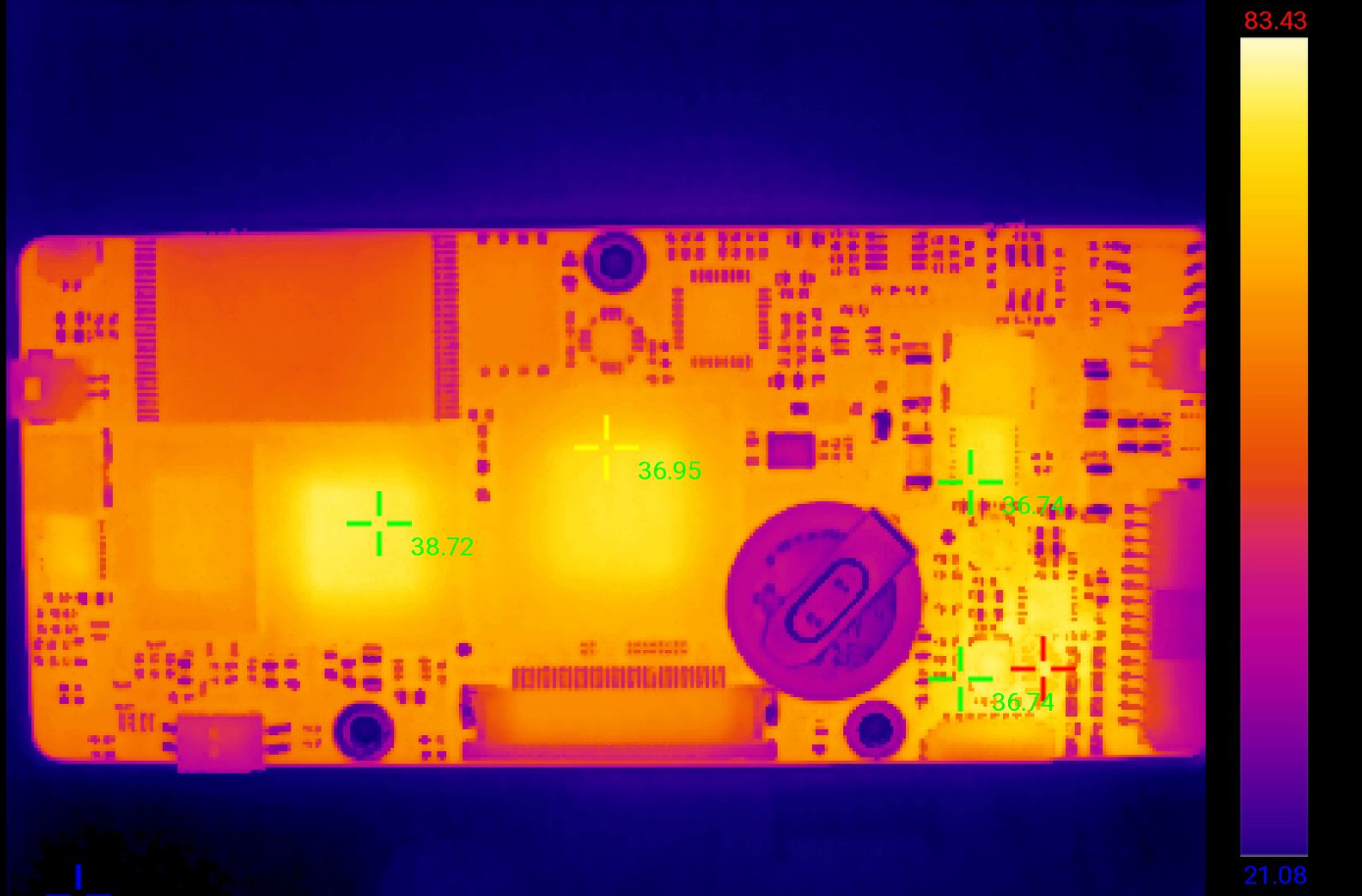

Thermal imaging device are essential tools in diagnosing and troubleshooting automotive circuit boards. They operate by detecting infrared radiation emitted from electronic components, allowing for the visualization of temperature distributions across the board. This capability is crucial for identifying overheating components, short circuits, and faulty connections that may lead to performance issues.

Infrared in thermometer are increasingly utilized in automotive circuit boards, providing significant advantages in quality control, thermal management, and performance evaluation. Here are some key applications:

Applications of Infrared Devices in Automotive Circuit Boards

Infrared heat camara is employed to assess the temperature distribution across automotive circuit boards during operation. This is crucial for detecting hotspots that could indicate potential failures or inefficiencies in electronic components. By visualizing the thermal profile, engineers can optimize designs to ensure that components operate within safe temperature ranges, thus enhancing reliability and longevity

During the manufacturing process of automotive electronics, infrared cameras are used for non-destructive testing to identify defects in circuit boards. By monitoring the thermal characteristics of the boards, manufacturers can detect issues such as solder joint failures or component misalignments before they lead to product failures. This proactive approach improves overall product quality and reduces waste

Infrared devices are utilized to evaluate the performance of various electronic components mounted on circuit boards. For example, during stress testing, infrared cameras can monitor how components react under different load conditions by tracking their temperature changes. This data helps engineers understand the thermal behavior of components and make necessary adjustments to improve performance

In power electronics applications within vehicles, managing heat dissipation is critical. Infrared thermography helps engineers design effective cooling solutions by identifying areas on circuit boards that generate excessive heat. By optimizing the layout and cooling strategies based on thermal data, manufacturers can enhance the efficiency and reliability of power electronics systems

Advanced inspection systems integrate infrared technology with automated processes to continuously monitor the thermal performance of circuit boards during production. These systems can quickly identify deviations from expected thermal profiles, allowing for immediate corrective actions. This integration enhances operational efficiency and ensures high-quality standards throughout the manufacturing process

6.Benefits of Using Infrared Devices for Automotive Circuit Boards

Non-Contact Measurement: Infrared technology allows for safe and non-invasive monitoring of temperature without interrupting the manufacturing or testing processes.

Real-Time Data: Immediate feedback on thermal performance enables quick adjustments and optimizations.

Enhanced Reliability: Early detection of potential issues leads to improved product quality and reduced risk of failures in automotive applications.

In summary, infrared devices play a vital role in the development and production of automotive circuit boards by improving quality control, enhancing thermal management, and ensuring reliable performance in various electronic systems within vehicles.

infrared thermal imaging temperature monitoring system for anode furnace is used for monitoring the temperature of the furnace wall and the solution in the high temperature smelting furnace

When working with kilns, proper cooling and maintenance are crucial for safety and efficiency. One critical step is kiln cooling and unloading, often referred to as "kiln unloading" or "kiln discharge." In this process, monitoring temperature and sealing any gaps are key to preventing heat loss and structural damage. Here’s how small...

In the world of kiln operation, success depends equally on artistic vision and technical precision. Mastering three key maintenance tools - small infrared cameras, kiln cement, and kiln Portland cement - can elevate your craft while protecting your investment. Let's explore how these solutions work together to create a maintenance sy...