Shocking Truth:

Over 25% of electrical fires start from simple connection issues that thermal cameras can spot weeks in advance.

Real-World Example:

During a factory maintenance check, a thermal camera reveals a circuit breaker glowing at 75°C (normal <35°C). Closer inspection shows a corroded connection causing overheating, with the plastic casing warping. Replacing the faulty component immediately avoids a fire risk—thermal cameras detect invisible heat signatures that signal impending electrical failures.

How It Works:

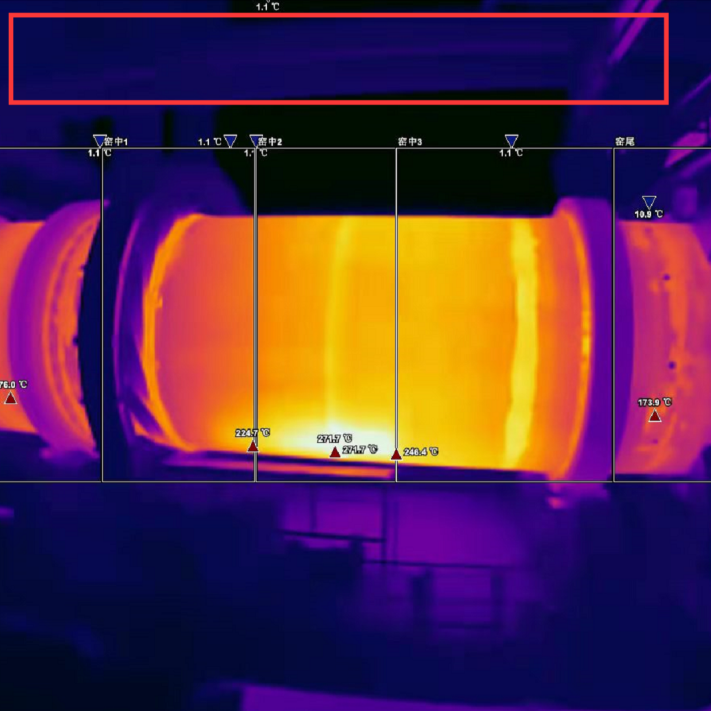

Scan panels/switches with thermal imaging small cameras

Hot connections show as bright yellow/white

Hot spots may indicate broken wires

3 Most Common Finds:

⚡ Loose wires (50% hotter than normal)

⚡ Overloaded circuits (whole panel "glowing")

⚡ Failing breakers (one side hotter)

Budget Tip:

While infrared imaging camera price starts around $2,000, many insurance companies offer discounts for using this prevention tech.

Maintaining your kiln properly ensures consistent results and prevents costly damage. Whether you're a ceramic artist or industrial operator, understanding proper unloading and maintenance techniques is crucial. This guide highlights three essential components for optimal kiln performance: small infrared cameras, kiln cement, and kil...

Read More