The Problem:

Rotary kilns can develop invisible hot spots that lead to:

✔ Sudden shutdowns costing $50,000+ per day

✔ Dangerous refractory explosions

✔ Wasted energy from uneven heating

How Thermal Imaging Small Devices Help:

These handheld tools act like "heat stethoscopes" for kilns:

Spot trouble areas in 10 us from safe distances

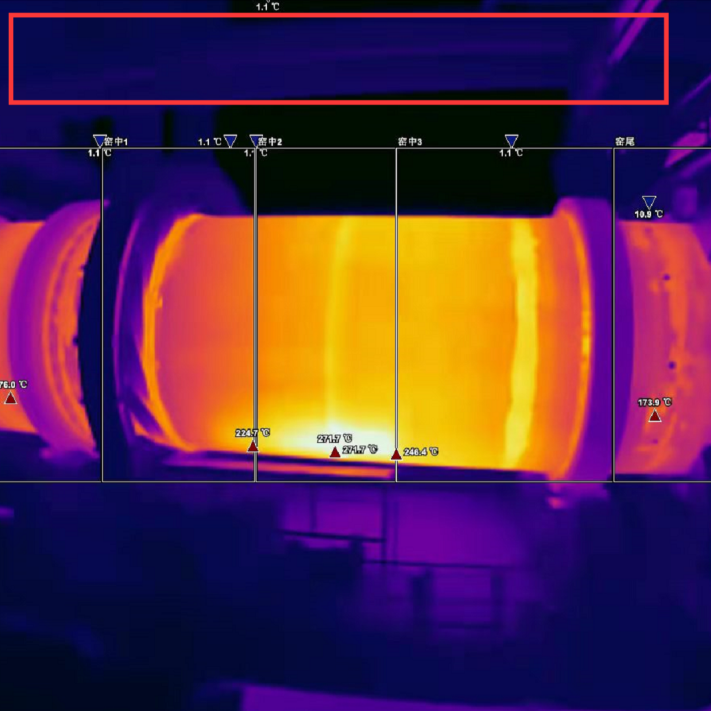

Create color-coded heat maps (blue=cool, red=hot)

Save months of downtime by catching issues early

Real-World Example:

A cement plant using infrared cameras thermal imaging found a hidden hot spot that could have caused a 3-week shutdown. The fix took 2 days.

What Matters Most When Choosing Equipment:

While infrared imaging camera price varies, look for:

→ Minimum 320x240 pixel resolution

→ Ability to measure up to 1500°F (815°C)

→ Easy-to-use analysis software

Maintaining your kiln properly ensures consistent results and prevents costly damage. Whether you're a ceramic artist or industrial operator, understanding proper unloading and maintenance techniques is crucial. This guide highlights three essential components for optimal kiln performance: small infrared cameras, kiln cement, and kil...

Read More