What are the advantages of short-wave temperature measurement?

Short-wave temperature measurement (ir camera for sale) has the following significant advantages, especially in the fields of industrial detection, remote sensing monitoring, high-temperature measurement, etc.:

一. Fast response speed, suitable for dynamic measurement

- Principle advantage: Short-wave radiation (wavelength of about 0.3-3μm) has high photon energy. The higher the temperature of the object, the greater the proportion of short-wave radiation energy. The temperature measuring instrument can quickly reflect temperature changes by capturing high-frequency radiation signals.

Application scenarios: Suitable for real-time monitoring of high-speed moving objects (such as hot-rolled steel parts, rocket tail flames) and transient high-temperature processes (such as explosions and welding pools) to avoid measurement deviations caused by delays.

二、Small environmental interference and high measurement accuracy

1. Strong resistance to water vapor/smoke interference

- When short-wave radiation is transmitted in the atmosphere, it is less affected by the absorption and scattering of gases such as water vapor and carbon dioxide (compared with long-wave radiation), and is suitable for humid, smoky or dusty environments (such as boiler interiors and metallurgical workshops).

2. Low emissivity effect

- The short-wave emissivity of most metals at high temperatures is more stable, and the emissivity can be further unified through surface coatings (such as high-temperature resistant paint), reducing measurement errors caused by differences in material properties.

Low background radiation interference

The short-wave radiation energy of low-temperature background (such as normal temperature environment) is extremely low. The instrument can ignore ambient light interference and focus on the high-temperature radiation signal of the target object.

三、 Suitable for high-temperature and extremely high-temperature measurements

- Wide measurement range: Short-wave temperature measurement technology is suitable for medium-high temperature to extremely high-temperature scenes (usually above 500℃, up to thousands of degrees Celsius), such as:

1. Steel smelting (blast furnace temperature monitoring), glass melting, and aircraft engine combustion chamber temperature measurement.

2. Astronomical observation (stellar surface temperature measurement), plasma physics experiments.

- Avoid signal saturation problems: Long-wave temperature measurement may cause a decrease in accuracy due to detector response saturation at extremely high temperatures, while short-wave detectors can maintain linear response by adjusting the band (such as near-infrared, visible light).

四、 High spatial resolution, suitable for small targets

- Advantages of optical focusing: The wavelength of short-wave radiation is shorter, and optical systems (such as lenses and optical fibers) can achieve narrower spot focusing (minimum down to micrometer level), which is suitable for:

1. Microelectronic components (chip hot spot detection), precision welding point temperature measurement.

2. Medical field (micro-area temperature monitoring of tissues during laser surgery).

五、 It can penetrate partially transparent/translucent materials

- Unique material compatibility: Short-wave radiation can penetrate partially transparent or translucent materials (such as glass, quartz, thin plastics), directly measure internal temperature without contacting or destroying the measured object:

1. Glass product processing (such as glass bottle annealing temperature monitoring).

2. Temperature monitoring during heat treatment of semiconductor wafers.

六、Convenient for multi-band data fusion and imaging

- Rich spectral information: Combined with multi-spectral or hyperspectral technology, the temperature can be calculated by the ratio of radiation intensity of different short-wave bands (such as dual-band colorimetric temperature measurement method), eliminating the influence of emissivity uncertainty and further improving accuracy.

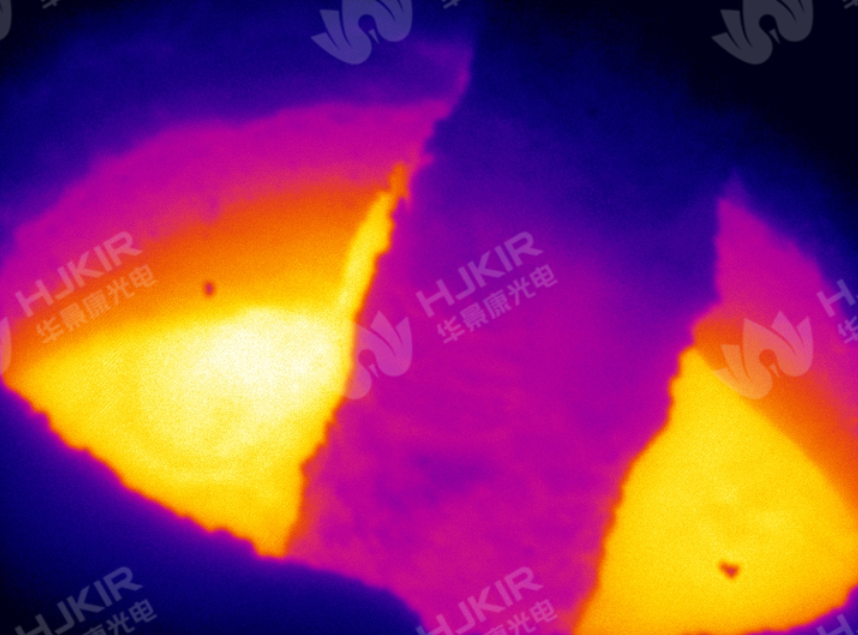

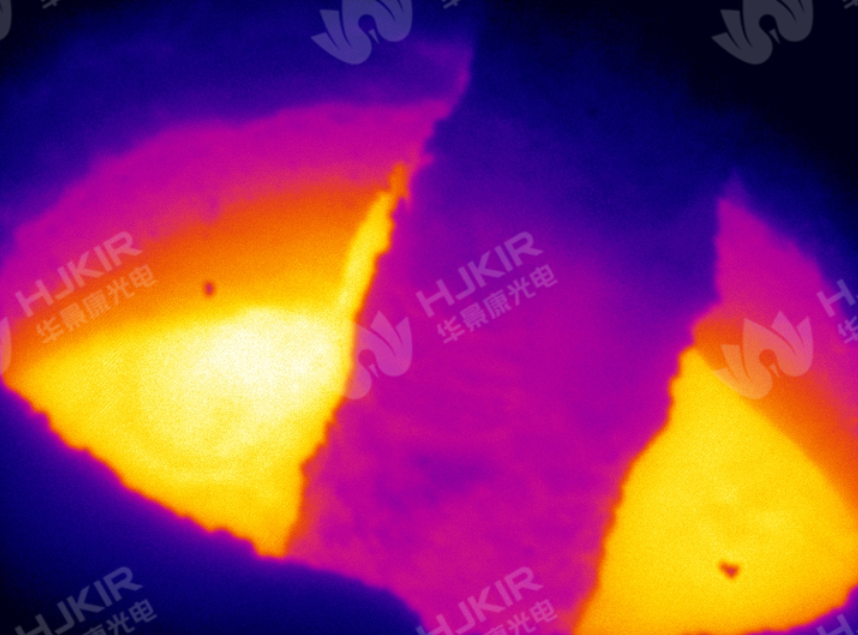

- Thermal imaging expansion: Short-wave thermal imagers can generate high-resolution temperature images for industrial quality inspection (such as circuit board thermal distribution analysis) and scientific imaging (such as combustion flame structure research).

七、High system integration and flexible application scenarios

- Miniaturization and non-contact characteristics: Short-wave temperature measuring instruments (such as portable infrared thermometers and fiber-optic sensors) can achieve lightweight design and support a variety of deployment methods such as handheld, vehicle-mounted, and drone-mounted. They are suitable for:

1. Outdoor power equipment inspection (such as high-voltage cable joint temperature measurement).

2. Aerospace field (satellite remote sensing of high-temperature areas on the surface, aircraft thermal protection layer monitoring).

Summary

The core advantages of short-wave temperature measurement can be summarized as: fast (fast response), accurate (strong anti-interference), high (high temperature applicability, high resolution), and penetrating (unique penetration). Its technical characteristics make it an irreplaceable temperature measurement method in industrial automation, scientific research monitoring, high-end manufacturing and other fields. In practical applications, it is necessary to select appropriate short-wave bands (such as near-infrared, visible light) and temperature measurement modes (single-point measurement or imaging) according to the temperature range, material properties and environmental conditions of the object being measured.