In the hydropower industry, the application of infrared thermal imaging technology is proving to be invaluable for enhancing equipment monitoring and preventive maintenance. This technology helps ensure the stability and efficiency of power generation systems by providing real-time insights into equipment conditions.

Key Applications of Infrared Thermal Imaging in Hydropower

- Real-Time Temperature Monitoring

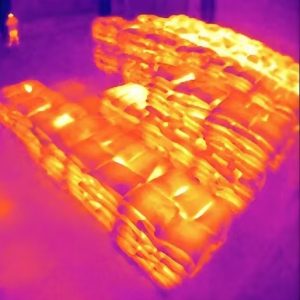

The infrared thermal imaging thermometer uses advanced non-contact infrared detection technology to quickly, accurately, conveniently and intuitively display the distribution of the surface temperature field of the measured object and measure the surface temperature of the object, with thermal vision camera price varying by model. It can quickly test the surface temperature reading of the object without direct contact with the surface of the measured object, and can reliably measure the surface temperature of hot, dangerous or difficult-to-reach objects. The infrared thermal imager has a very fast measurement speed and can intuitively and continuously test the temperature changes on the surface of the object.

- Predictive Maintenance

The ability to perform non-contact inspections allows for predictive maintenance strategies. Regular thermal imaging inspections help operators schedule maintenance activities based on actual equipment conditions rather than relying solely on time-based schedules. This approach reduces maintenance costs and improves overall system reliability.

- Leak Detection

Thermal imaging can effectively identify leaks in water pipelines and hydraulic systems. By detecting temperature variations indicative of leaks, operators can address issues promptly, minimizing water loss and maintaining operational efficiency.

- Dam Integrity Monitoring

Handheld and fixed thermal cameras are employed to monitor the temperature distribution on dam surfaces. Any significant temperature changes may indicate structural problems or seepage, enabling timely interventions to ensure dam safety.

- Electrical Equipment Inspection

Thermal imaging is crucial for inspecting electrical components such as switchgear and circuit breakers for overheating or faults. Early detection of electrical issues helps prevent potential hazards and ensures the reliability of the electrical supply.

- Cooling System Assessment

The technology is also used to assess cooling systems' performance, identifying inefficiencies that could lead to overheating or equipment failure.

- Security Monitoring

Infrared cameras enhance security by detecting unauthorized access to sensitive areas of hydropower facilities, even in low-light conditions.

Conclusion

Integrating ir camera price considerations into hydropower operations significantly elevates monitoring capabilities and proactive maintenance strategies. By delivering real-time insights into equipment health, this technology ensures efficient and safe power generation while aligning with the sustainability objectives of the renewable energy sector. As the global demand for clean energy grows, advanced monitoring technologies—with careful attention to ir camera price—will play a pivotal role in optimizing hydropower operations and safeguarding long-term energy security.