What is the principle of infrared medium wave temperature measurement?

The principle of medium-wave (MW) infrared thermometry (operating in the 3–5μm wavelength range) is rooted in Planck’s Law of Blackbody Radiation and the selective interaction of thermal radiation with matter. Here’s a detailed explanation:

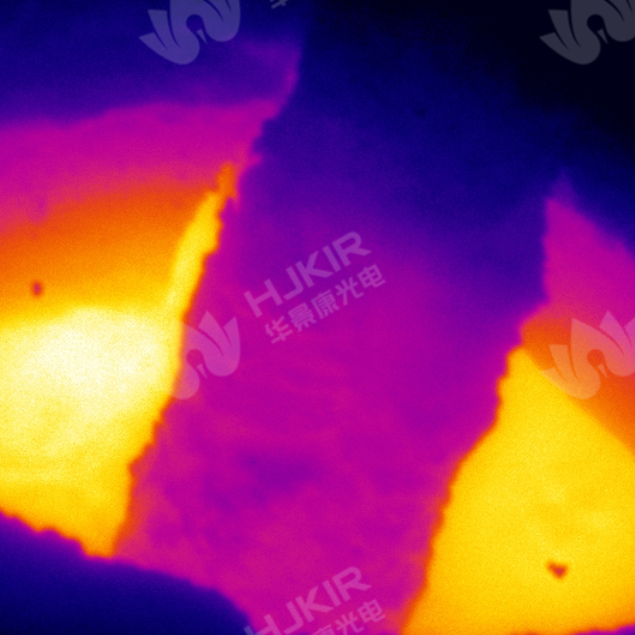

All objects above absolute zero emit thermal radiation proportional to their temperature. Mwir camera is a tool.

- Planck’s Law describes the spectral radiance B(λ,T) of a blackbody (ideal emitter) as:B(λ,T)=λ52hc2⋅eλkThc−11

where:

- λ= wavelength

- T= absolute temperature (Kelvin)

- h= Planck constant, c= speed of light, k= Boltzmann constant

- Key Insight for MW:

- At high temperatures (800–2000°C), the peak of the blackbody radiation curve shifts toward shorter wavelengths (MW range).

- MW sensors are optimized to detect this intense radiation, providing high signal-to-noise ratios for accurate temperature measurements.

Real-world objects are not perfect blackbodies; their radiation depends on emissivity (ϵ)—a material-specific factor (0 ≤ ϵ ≤ 1) that describes how efficiently they emit radiation. High speed thermal camera is a tool.

- MW Advantages for Materials:

- Metals: At high temperatures, we use high definition infrared camera, metals have relatively stable emissivity in the MW range (e.g., steel ≈ 0.1–0.3), reducing errors from surface reflections compared to long-wave infrared (8–14μm).

- Transparent/Semi-Transparent Materials: MW radiation penetrates materials like glass, ceramics, or plastics more effectively than long-wave infrared, enabling measurement of internal temperatures (e.g., molten glass in furnaces).

- Plasmas/Gases: MW interacts strongly with ionized gases and hot plasmas, making it suitable for high-energy physics research.

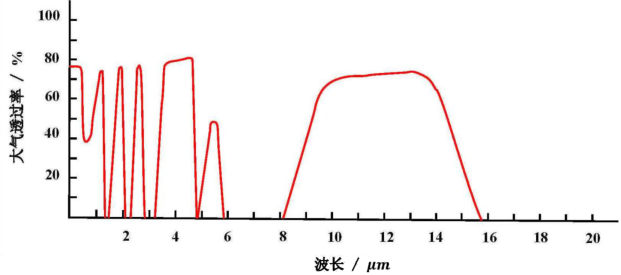

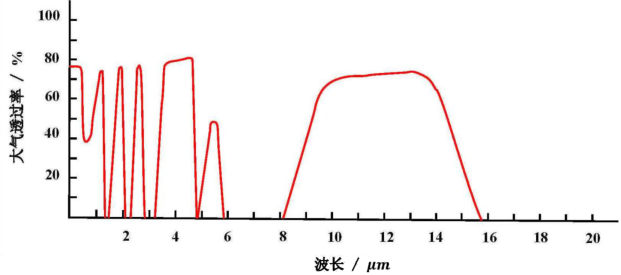

The Earth’s atmosphere absorbs or scatters infrared radiation at specific wavelengths.

- MW Atmospheric Window:

- The 3–5μm band experiences minimal absorption by water vapor, CO₂, and aerosols (compared to other IR bands), making it ideal for:

- Long-range measurements in smoky/foggy environments (e.g., firefighting, industrial chimneys).

- Aerospace applications (e.g., missile guidance through haze).

- In contrast, the long-wave (8–14μm) window is more affected by water vapor, limiting range in humid conditions.

MW thermometry relies on specialized detectors:

- Quantum-Based Detectors:

- Indium Antimonide (InSb): Sensitive to 3–5μm, widely used in high-temperature industrial and military applications.

- Mercury-Cadmium-Telluride (HgCdTe, MCT): Adjustable sensitivity across MW and long-wave bands, offering high detectivity for low-light or fast-response scenarios (e.g., missile seekers).

- Key Operational Features:

- Fast Response Time: Nanosecond to millisecond-level speed, critical for tracking transient events (e.g., spark ignition, plasma dynamics).

- High Spatial Resolution: MW cameras often achieve sub-millimeter pixel sizes, enabling detailed thermal imaging of small components (e.g., microchips, turbine blades).

MW thermometers calculate temperature by:

- Measuring the radiant power in the 3–5μm band using calibrated detectors.

- Applying the Stefan-Boltzmann Law for total radiation or solving Planck’s Law iteratively, accounting for:

- Emissivity (ϵ) of the target material.

- Atmospheric attenuation (e.g., path length, humidity, particulate matter).

- Reflected background radiation (corrected via ambient temperature compensation).

- For dual-wavelength (ratio) thermometers, the intensity ratio at two MW wavelengths cancels out emissivity effects, enabling highly accurate measurements even for unknown or changing surface properties.

| Aspect |

Medium-Wave (3–5μm) |

Long-Wave (8–14μm) |

| Optimal Temperature |

High (800–2000°C; peak radiation in MW) |

Low to medium (20–1000°C) |

| Material Emissivity |

Stable for metals; better penetration in glass/plasmas |

Variable for metals (highly reflective); surface-only for solids |

| Atmospheric Penetration |

Better in smoke, dust, or haze |

Affected by water vapor and humidity |

| Typical Applications |

Furnaces, turbines, missile guidance |

Building inspections, electrical panels, humans |

Medium-wave infrared thermometry leverages Planck’s radiation law, material-specific emissivity characteristics, and atmospheric transmission windows to accurately measure high-temperature targets in challenging environments. Its combination of quantum detectors, fast response, and wavelength-specific advantages makes it indispensable for industries and research fields requiring precision in harsh, high-energy, or obscured conditions. HJK infrared camera: mwir camera,high definition infrared camera,high speed thermal camera