Background:

Thermal imaging device have become a crucial tool in the automotive industry, especially in the development and monitoring of heating wire systems. Heating wires, commonly integrated into windshields and rear windows, are designed to prevent fogging and icing, ensuring clear visibility and safer driving conditions. Infrared cameras enable precise temperature measurement and visualization of heat distribution across the heating wires, providing invaluable data during design, testing, and maintenance. Their ability to detect uneven heating or potential faults in real-time improves the overall reliability and efficiency of these systems. Additionally, infrared technology supports energy optimization, helping manufacturers achieve higher performance while adhering to stricter energy efficiency and environmental standards. This innovative approach underscores the importance of infrared cameras in enhancing automotive safety and sustainability.

Infrared in thermometer have various applications in heating wires, particularly in industrial and automotive contexts. Here are some notable case studies:

Applications of Infrared Devices in Heating Wires

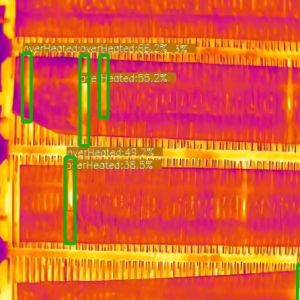

Infrared heat camara is used to monitor the heating elements embedded in automotive rear windows. During production, engineers utilize infrared cameras to capture thermal images of the heating wires as they heat up. This process ensures that the heat is evenly distributed across the glass, preventing localized overheating that could lead to glass breakage. The infrared analysis software helps assess the temperature distribution and identify any irregularities in the heating wire's performance, ensuring safe and effective defrosting capabilities during cold weather conditions

In manufacturing environments, infrared thermography serves as a non-destructive testing method for heating wires in various applications, including electric heaters and industrial ovens. By detecting temperature variations, manufacturers can identify defects in the heating elements before they lead to failures. This proactive approach enhances product reliability and safety while reducing waste and rework costs

Infrared devices are employed to analyze the performance of resistance heating wires used in different applications. For instance, in food processing or textile drying, heating wire performance can be optimized by monitoring the temperature profiles of heating wires. This allows for adjustments to be made to improve efficiency and ensure that products are heated uniformly without damaging sensitive materials

Some advanced systems integrate infrared cameras with programmable logic controllers (PLCs) for automated inspection of heating wires. These systems can quickly detect broken or malfunctioning wires by analyzing temperature data in real-time. When anomalies are detected, the system can trigger alerts or shut down operations to prevent further issues, thus enhancing operational safety and efficiency

5.Benefits of Using Infrared Devices for Heating Wires

Non-Contact Measurement: Infrared technology allows for non-invasive monitoring of temperature without disrupting the heating process.

Real-Time Analysis: The ability to provide immediate feedback on temperature distribution helps optimize processes and prevent failures.

Enhanced Safety: Early detection of potential issues reduces the risk of accidents related to overheating or equipment failure.

In summary, infrared devices play a crucial role in monitoring and analyzing heating wires across various industries, particularly in automotive applications where safety and performance are paramount. Their ability to provide real-time data enhances quality control and operational efficiency while ensuring compliance with safety standards.

infrared thermal imaging technology new energy batteries Temperature monitoring Thermal management optimization Fault diagnosis

infrared thermal imaging Long-distance, non-contact temperature measurement Support alarm function Real-time monitoring of kiln lining conditions

HJK Professional customized infrared thermal imaging technology with higher fault detection accuracy, can accurately locate each anode and cathode plate, also accure detected the short-circuited plate greatly improving the detection efficiency.