Below are some application scenarios of infrared medium wave temperature measurement:

- Metallurgy & Metal Processing:

- Measuring temperatures of molten metals (e.g., steel, aluminum) in furnaces, ladles, or continuous casting lines. MW’s high-temperature sensitivity (800–2000°C) and resistance to metal surface reflections ensure accurate readings.

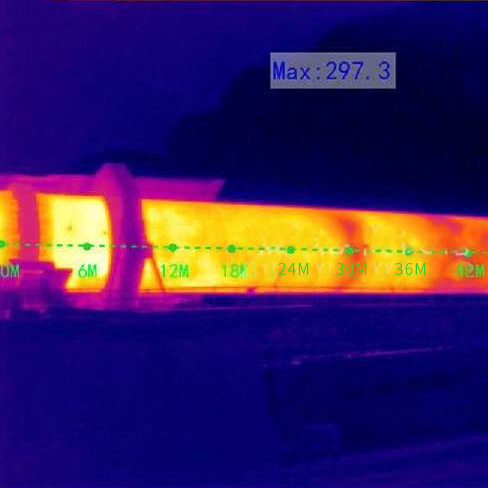

- Monitoring hot-rolling mills, heat treatment furnaces, and welding processes for real-time temperature control.

- Glass & Ceramics Industry:

- Optimizing glass melting, annealing, and forming processes by measuring internal temperatures of semi-transparent glass sheets (MW penetrates glass more effectively than long-wave infrared).

- Detecting thermal defects in ceramic kilns or tile production lines.

- Semiconductor & Electronics:

- Thermal mapping of microchips, PCBs, and solder joints during fabrication (MW’s high spatial resolution identifies hotspots in tiny components).

- Monitoring rapid thermal processing (RTP) chambers for precise wafer temperature control.

- Aeroengine & Turbine Inspection:

- Measuring blade temperatures in jet engines or gas turbines during operation (MW’s fast response time captures transient thermal dynamics).

- Detecting thermal barrier coating (TBC) degradation on turbine components.

- Missile Guidance & Surveillance:

- MW sensors are used in infrared seekers for missiles due to their ability to penetrate atmospheric haze and track high-temperature targets (e.g., aircraft engines) with high precision.

- Unmanned aerial vehicles (UAVs) equipped with MW cameras for reconnaissance in smoky or dusty environments.

- Fire Source Detection in Smoke:

- MW cameras penetrate thick smoke (due to the 3–5μm atmospheric window) to locate hotspots in burning buildings, wildfires, or industrial fires, guiding firefighting efforts.

- Search & Rescue:

- Identifying trapped individuals in low-visibility conditions by detecting body heat (MW is less affected by ambient light than visible-spectrum cameras).

- Renewable Energy:

- Monitoring solar thermal plants (e.g., concentrating solar power systems) to optimize heat transfer fluid temperatures.

- Inspecting wind turbine gearboxes or photovoltaic (PV) inverters for overheating.

- Traditional Power Plants:

- Thermally analyzing boiler tubes, steam turbines, and electrical switchyards for early fault detection (e.g., loose connections, insulation failures).

- High-Energy Physics & Plasma Research:

- Measuring ultra-high temperatures in plasma reactors, fusion experiments (e.g., tokamaks), or laser-induced plasmas (MW’s fast response and high-temperature accuracy are critical).

- Combustion & Fluid Dynamics Studies:

- Capturing transient temperature fields in combustion chambers or supersonic flows using MW thermography for aerospace or automotive R&D.

- Volcanology & Geothermal Monitoring:

- Tracking lava flow temperatures or geothermal vent activity in remote or hazardous areas (MW’s atmospheric penetration aids data collection in volcanic ash).

- Precision Agriculture:

- Assessing crop stress (e.g., water deficiency) by measuring leaf surface temperatures with drone-mounted MW sensors (works under varying lighting conditions).

- Non-Invasive Thermal Imaging:

- Experimental use in dermatology for detecting skin lesions or burns (MW’s penetration depth may offer insights into subsurface thermal structures).

- Bioprocess Monitoring:

- Controlling fermentation temperatures in bioreactors or monitoring cell culture thermal stability in pharmaceutical labs.

- Perimeter Security:

- MW cameras detect intruders in complete darkness or foggy conditions, as they are unaffected by visible light and offer better range than long-wave infrared in harsh weather.

- Vehicle & Cargo Inspection:

- Identifying hidden heat sources (e.g., overheating batteries, smuggled goods) in trucks or containers at border checkpoints.

| Scenario |

Why MW Thermometry is Ideal |

| High-temperature targets |

Aligns with Planck’s law for intense radiation at 800–2000°C |

| Smoky/dusty environments |

Better atmospheric penetration than long-wave infrared |

| Small or fast-moving objects |

Higher spatial resolution and nanosecond-level response |

| Metal/transparent materials |

Stable emissivity and improved penetration depth |

Medium-wave infrared thermometry excels in high-temperature, high-speed, and harsh-environment applications where precision, reliability, and environmental robustness are critical. Its unique advantages in atmospheric penetration, material compatibility, and fast response make it a preferred choice across industrial, defense, research, and public safety sectors, often outperforming long-wave infrared in specialized scenarios.