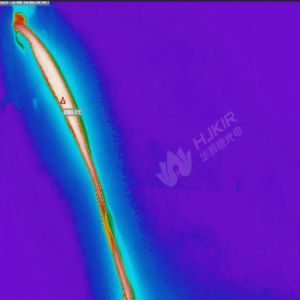

The anode furnace is located after the converter and before the electrolytic refining in the pyrometallurgical copper smelting process of the copper plant. Infrared thermal imaging can monitor the temperature distribution of the anode furnace in real time, warn of refractory wear and cooling system failures, and assist in process optimization and safe and efficient production.

The infrared heat camara temperature monitoring system for anode furnace is a system specially used for monitoring the temperature of the furnace wall and the solution in the high-temperature smelting furnace. The furnace wall uses a long-wave infrared sensor, and the solution in the furnace uses a short-wave infrared sensor. They are respectively equipped with high-performance lenses and excellent imaging processing circuits, and are embedded with advanced image processing algorithms. Thermal imaging device has low noise, high protection level, strong environmental adaptability, low power consumption, fast startup, excellent imaging quality, wide temperature measurement range, and accurate temperature measurement. It is very suitable for high-temperature temperature measurement on-site applications.

Real-time display: The full radiation thermal map is displayed in real time. The on-duty personnel can view the temperature at any location, record, take photos, analyze abnormal situations, and issue professional inspection reports;

Temperature tracking: Automatically analyze the temperature rise trend of the entire screen or specific areas of the thermal image to find potential danger areas early;

IR infrared camera has data capture: Thermal imaging image data can be collected regularly for later analysis;

High temperature trigger shooting and alarm: When temperature abnormalities occur, the monitoring background can be discovered in time, triggering the alarm, the sound and light alarm module will sound an alarm, and the software background will take pictures of the incident;

Fault self-diagnosis: When the terminal device fails, the system can remind the on-duty personnel;

Custom alarm thresholds and levels: The system can define 4 different alarm thresholds and levels to assist staff in evaluating the urgency and development trend of potential dangers;

Automatic classification storage: Monitoring data, abnormal data and alarm information will be automatically stored in the corresponding equipment data column, which can be quickly and accurately called for analysis;

Report function: Various reports can be customized according to customer requirements and exported to Word format;

Temperature curve: The software can observe the real-time temperature curve of the temperature measurement object and make trend judgment.

infrared thermal imaging technology improved detection efficiency, real-time monitoring, preventive maintenance, safety improvement and economic improvement

HJKIR developed a new type of continuous temperature measurement system for molten iron, which can directly measure the temperature of the iron flow at the taphole during tapping and more directly and accurately represent the state and change process of the physical heat of the furnace. At the same time, it has the outstanding characteristics of...

infrared thermal imaging technology is used for high temperature detection of heating furnaces with high temperature resistant infrared equipment