Background

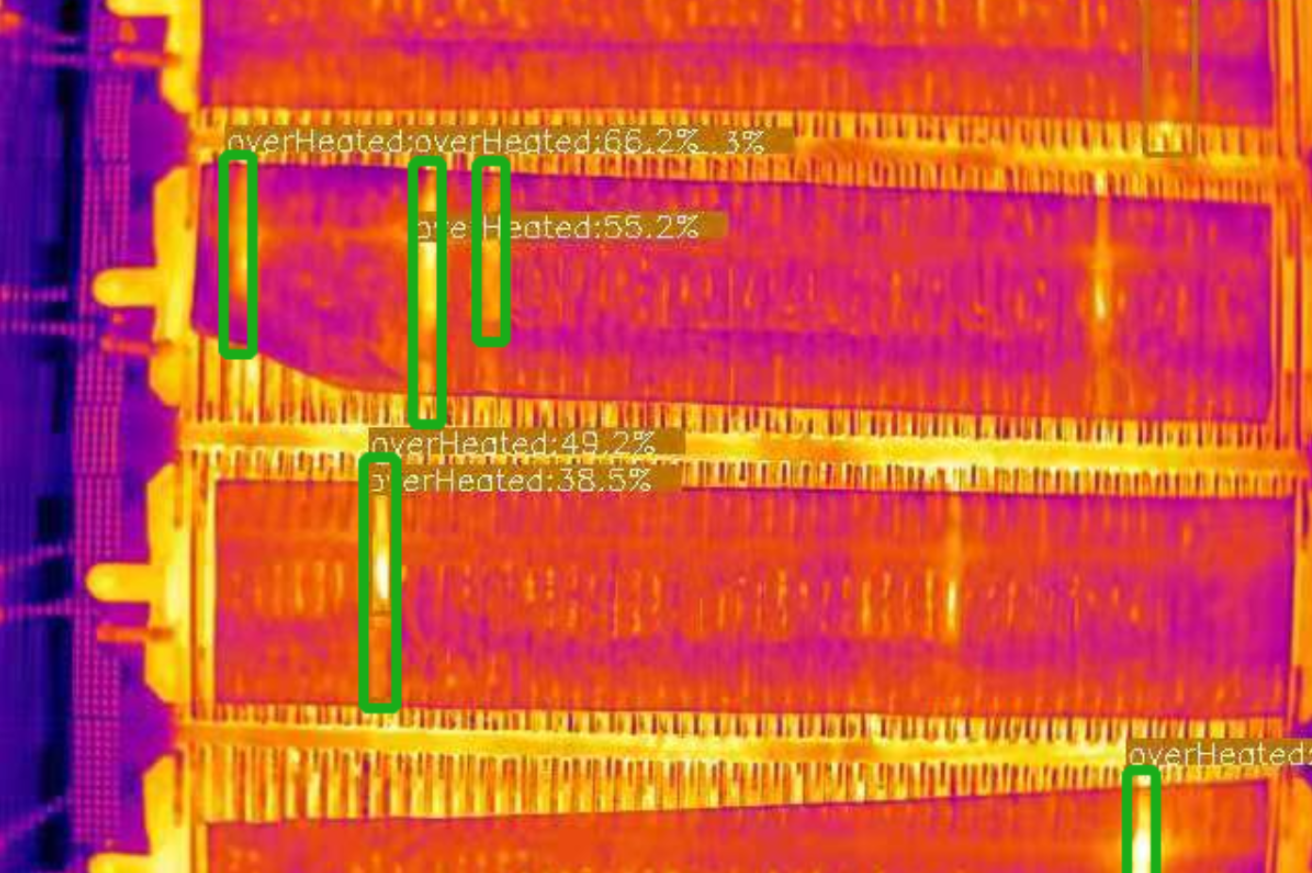

During the accumulation of cathode copper in the electrolytic cell, local short circuits sometimes occur, which will cause a large amount of power loss and high temperature, seriously affecting the normal production of cathode copper. At present, manual detection and other methods are generally used to detect the occurrence of short circuits, which have problems such as low detection efficiency, high labor intensity of workers, and harm to health. Therefore, timely detection and accurate positioning of the short circuit fault of the plate in the electrolytic cell has become one of the important conditions for electrolytic copper production. It is related to power efficiency and product quality. The traditional operation method is inefficient and has safety hazards. After a short circuit fault occurs in the plate of the electrolytic cell, the temperature rises sharply. By using thermal cameras to fully monitor the electrolytic cell, the short-circuited plate can be accurately detected and located, greatly improving the detection efficiency.

Advantagies

When working with kilns, proper cooling and maintenance are crucial for safety and efficiency. One critical step is kiln cooling and unloading, often referred to as "kiln unloading" or "kiln discharge." In this process, monitoring temperature and sealing any gaps are key to preventing heat loss and structural damage. Here’s how small...

Infrared thermal imager solution for metallurgy, application sence is Ladle, hjk system establish a surface temperature database for each ladle use cycle ans 360° all-round temperature detection of the package, and 3D schematic diagram shows the temperature field distribution of the package.