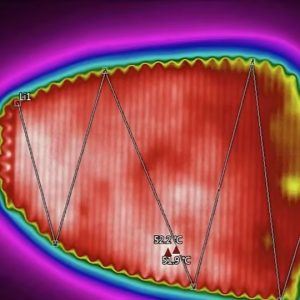

The PS converter is located after the copper concentrate is smelted and before the crude copper is refined in the pyrometallurgical copper smelting process of the copper plant. Infrared thermal imaging achieves safety protection, efficiency improvement, consumption reduction and precise temperature control by real-time monitoring of the PS converter furnace temperature distribution, early warning of equipment failures and optimization of process parameters.

HIRDA-PS type The PS converter infrared thermal imaging intelligent monitoring system is a system specially designed for high temperature metal smelting. The furnace temperature monitoring system consists of a high-temperature infrared in thermometer, an electric control box, an algorithm server and a customer Centrally monitor and manage the equipment on the job site and transmit it through a digital transmission network Realize PS Collection, analysis, and location of high-temperature points of converter wall temperature. Automatic alarm and other functions.

Ir video camera has all-weather passive thermal imaging function;

Use self-developed temperature measurement and correction algorithm to achieve accurate temperature measurement;

Infrarood camera has strong environmental adaptability, can be used in harsh environments such as high temperature and high dust;

Full range temperature detection of furnace wall to fully display the temperature field distribution of furnace body;

Automatic positioning and warning of high temperature areas in square decimeters;

Establish a furnace wall surface temperature database;

Build a corresponding model between refractory material thickness and furnace surface temperature;

Open interface, providing SDK Development kit, available with DCS、 PLC Waiting for system connection.

The high temperature resistant endoscope infrared thermal imaging thermometer is used to monitor the temperature of the water wall in real time by inserting the lens into the boiler, remotely view the status of the water wall, and actively make corrections according to the detection information to avoid abnormal situations such as boiler damage.

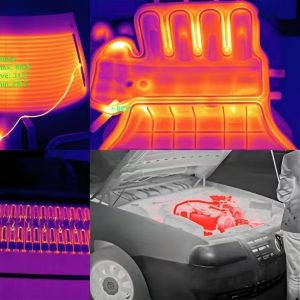

Infrared cameras have become a crucial tool in the automotive industry,infrared devices play a crucial role in monitoring and analyzing heating wires across various industries

Infrared thermal imaging is used to monitor the temperature distribution across various engine components, such as cylinder walls and exhaust manifolds.Infrared cameras help in detecting faults within the engine by visualizing temperature changes that occur due to mechanical failures.