In an era where precision and efficiency define industrial success, forward-thinking kiln operators are revolutionizing their maintenance strategies. By harnessing the power of small infrared cameras, kiln cement, and kiln Portland cement, modern facilities are achieving unprecedented levels of performance and reliability. This article explores how these three critical components form the foundation of 21st-century kiln maintenance.

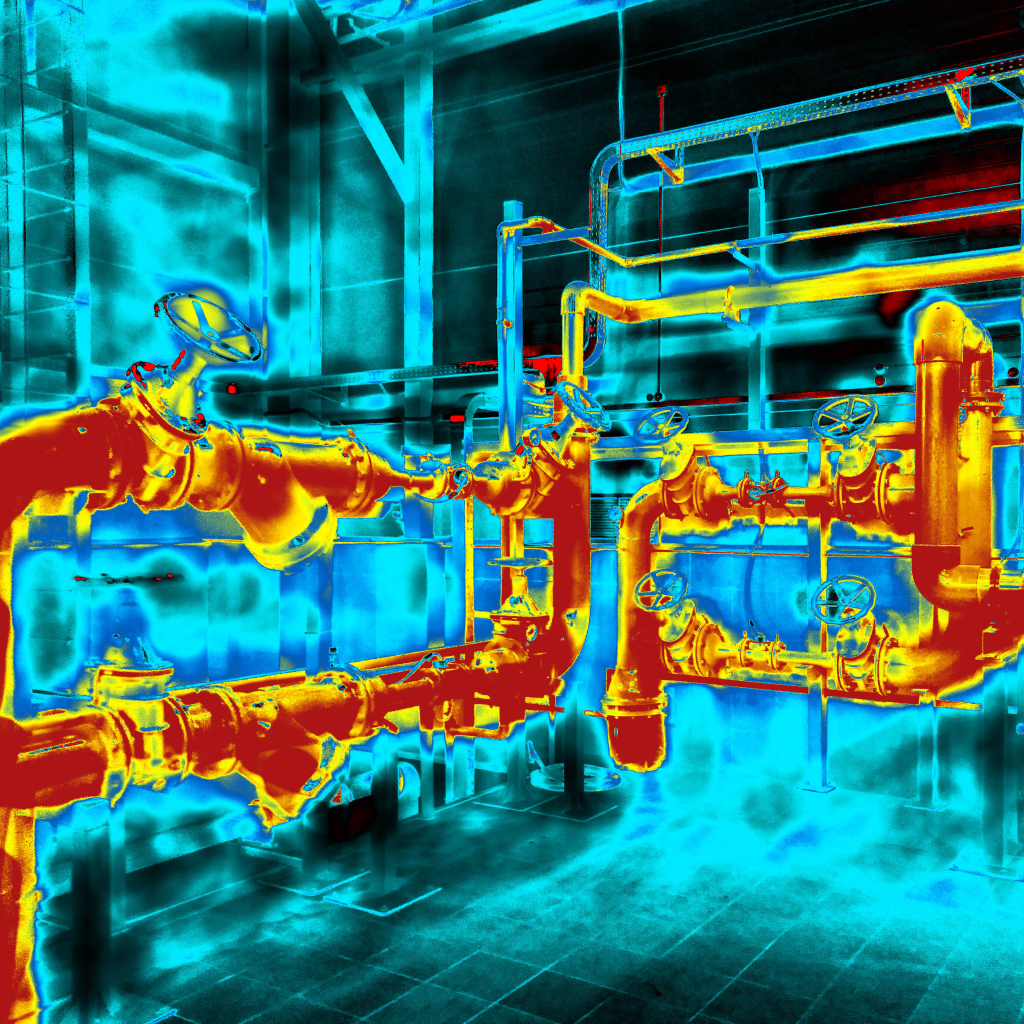

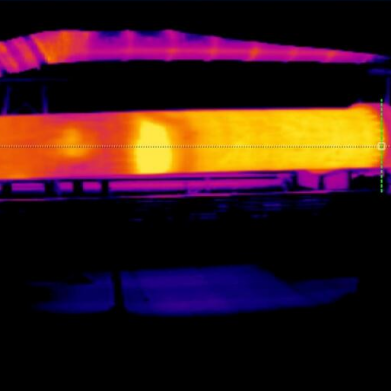

1. Small Infrared Cameras: The Eyes of Modern Kiln Maintenance

Today's small infrared cameras represent a quantum leap in thermal monitoring technology, offering:

Smart Monitoring Features:

AI-powered predictive failure analysis

Wireless mesh networking for facility-wide monitoring

Automated thermal anomaly detection

Integration with IoT platforms for real-time alerts

Cutting-Edge Applications:

Continuous process optimization through thermal pattern recognition

Remote expert diagnostics via cloud sharing

Energy efficiency benchmarking

Predictive maintenance scheduling

2. Kiln Cement: The Intelligent Sealant Solution

Next-generation kiln cement formulations now deliver:

Smart Material Advancements:

Self-healing microcapsule technology

Phase-change thermal regulation properties

Conductive additives for embedded sensors

Eco-friendly, low-carbon footprint formulations

Advanced Application Methods:

Robotic application systems for large-scale operations

3D printing for precision repairs

Smart curing monitoring with embedded sensors

Automated inventory tracking via RFID tags

3. Kiln Portland Cement: The Future of Structural Integrity

Revolutionary kiln Portland cement technologies now include:

Breakthrough Formulations:

Graphene-enhanced composites

Self-sensing stress-responsive materials

Ultra-high early strength variants

Carbon-negative production processes

Future-Forward Repair Techniques:

Augmented reality-assisted repair guidance

Drone-assisted damage assessment

Automated mixing and application systems

Blockchain-based quality verification

The Smart Maintenance Ecosystem

Digital Twin Integration

Create virtual kiln models synchronized with thermal imaging data

Simulate repair scenarios before physical intervention

Predict long-term wear patterns

Prescriptive Maintenance

AI-driven repair recommendations

Automated material ordering systems

Robotic repair execution

Performance Optimization

Continuous efficiency monitoring

Adaptive firing program adjustments

Real-time energy consumption analysis

Industry 4.0 Implementation Tips

Start with pilot programs for specific kiln zones

Prioritize staff training in new technologies

Implement phased technology integration

Establish key performance indicators for ROI measurement

Why Smart Maintenance Matters

40-60% reduction in maintenance costs

99.5% kiln availability rates

30% energy savings through optimized operations

Complete digital traceability for quality assurance

Future-proof operations against evolving regulations

For operations ready to embrace the future, we offer:

Smart maintenance technology audits

Customized digital transformation roadmaps

Integrated solution packages

Continuous improvement programs

The kilns of tomorrow demand maintenance solutions that are as advanced as the processes they support. By combining small infrared cameras, kiln cement, and kiln Portland cement with cutting-edge digital technologies, forward-looking operations are setting new standards for performance, efficiency, and reliability in thermal processing.

Invisible Dangers Thermal Cameras Reveal:✔ Gas leaks (shows as "cold clouds")✔ Tank leaks (wet areas look different)✔ Pump failures (abnormal heat patterns) Why Workers Love These Tools: Thermal imaging small cameras fit in tool belts No need to shut down equipment Takes 1/10th the time of old inspection methods Case Study:A refi...

Read More

In today's rapidly evolving industrial landscape, kiln operators face increasing pressure to maximize uptime while minimizing costs. This paradigm shift has given rise to a new era of predictive maintenance powered by three game-changing technologies: small infrared cameras, kiln cement, and kiln Portland cement. Let's examine how th...

Read More