Optimize the thermal efficiency of the sintering process, reduce energy consumption, adjust the amount and distribution of solid fuel according to the temperature distribution of the material layer, avoid heat waste caused by excessive fuel or incomplete sintering caused by insufficient fuel, and reduce fuel consumption per ton of ore (such as reducing coke powder consumption by 5~10kg/t).

The Problem:Rotary kilns can develop invisible hot spots that lead to:✔ Sudden shutdowns costing $50,000+ per day✔ Dangerous refractory explosions✔ Wasted energy from uneven heating How Thermal Imaging Small Devices Help:These handheld tools act like "heat stethoscopes" for kilns: Spot trouble areas in 10 us from safe distances ...

Read More

In an era where precision and efficiency define industrial success, forward-thinking kiln operators are revolutionizing their maintenance strategies. By harnessing the power of small infrared cameras, kiln cement, and kiln Portland cement, modern facilities are achieving unprecedented levels of performance and reliability. This artic...

Read More

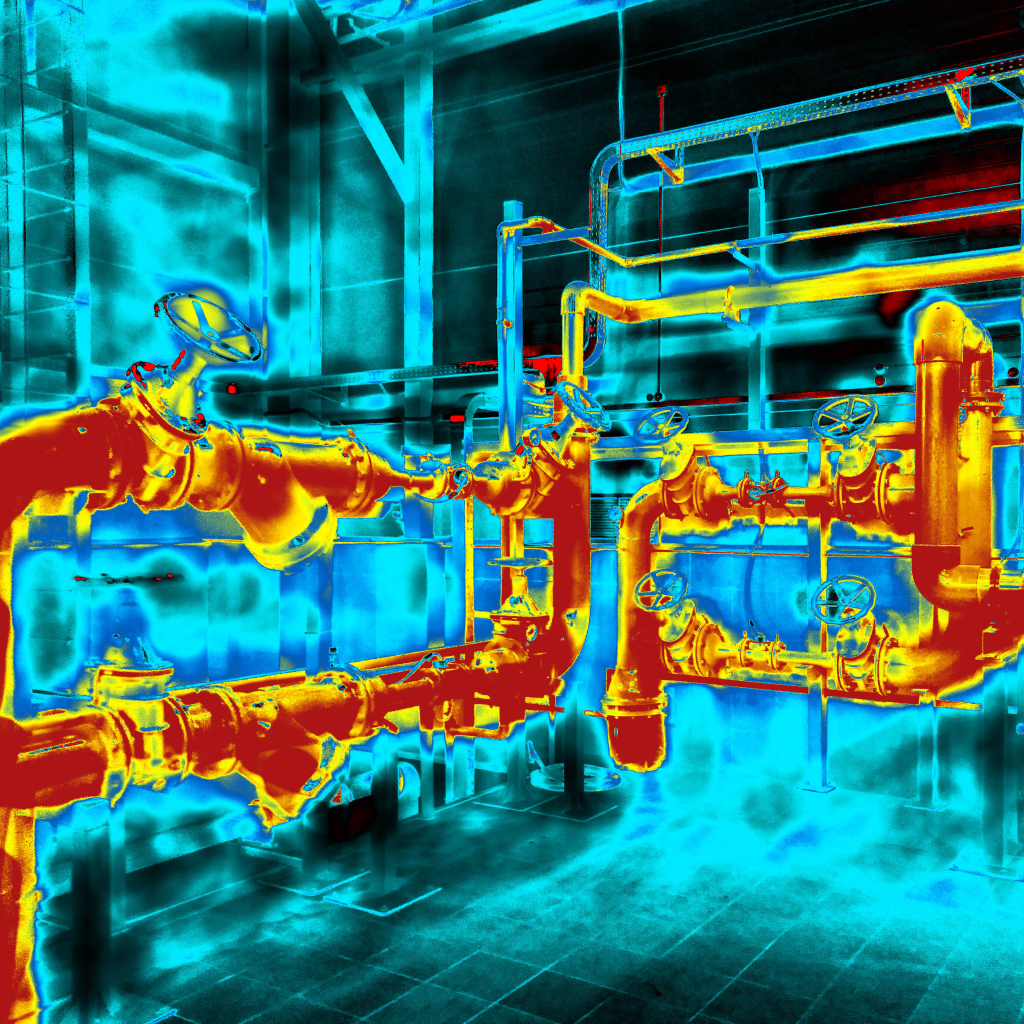

Invisible Dangers Thermal Cameras Reveal:✔ Gas leaks (shows as "cold clouds")✔ Tank leaks (wet areas look different)✔ Pump failures (abnormal heat patterns) Why Workers Love These Tools: Thermal imaging small cameras fit in tool belts No need to shut down equipment Takes 1/10th the time of old inspection methods Case Study:A refi...

Read More