What are the benefits of long wave temperature measurement?

The advantages of long-wave (LW) infrared thermometry, mwir camera (operating in the 8–14μm wavelength range) arise from its unique interaction with materials, atmospheric conditions, and sensor technology. Here are the key benefits:

- Most non-metallic materials (e.g., plastics, ceramics, paints, human skin) have high and stable emissivity in the 8–14μm band.

- This simplifies temperature measurement, as emissivity corrections are minimal or pre-calibrated for common surfaces.

- Example: In building diagnostics, LW thermography easily detects heat leaks through walls without complex surface adjustments.

- LW radiation is primarily reflected or emitted from the surface of solids (penetration depth < 1μm for most materials).

- This makes it ideal for non-destructive surface temperature mapping, such as:

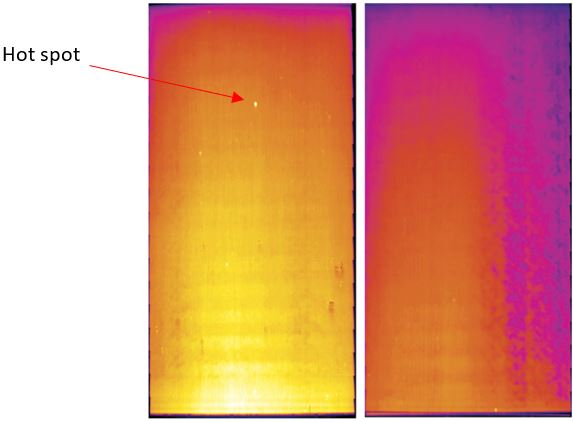

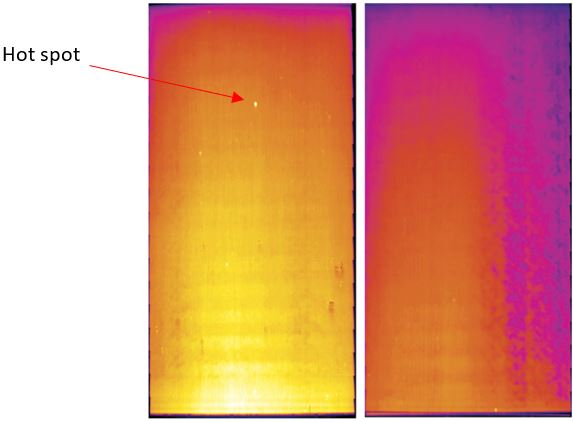

- Inspecting electrical panels for hotspots.

- Monitoring skin temperature in medical applications (e.g., fever screening).

- Quality control in manufacturing (e.g., detecting coating defects).

- While the 8–14μm band high definition infrared camera is slightly affected by water vapor, it remains effective in most ambient conditions (e.g., indoor environments, moderate humidity).

- Unlike medium-wave (MW) infrared, LW does not require specialized corrections for typical atmospheric moisture, making it user-friendly for general-purpose applications.

- LW detectors high speed thermal camera(e.g., microbolometers) are non-cooled and require no cryogenic cooling, reducing hardware complexity and cost.

- This enables compact, portable devices (e.g., handheld thermal cameras, drone-mounted LW sensors) widely used in:

- Firefighting (to visualize heat behind smoke).

- Renewable energy (solar panel efficiency checks).

- Automotive safety (night vision systems).

- The Planck radiation curve peaks in the LW range for objects at low to medium temperatures (20–1000°C).

- LW sensors excel at detecting subtle thermal differences in these ranges, e.g.:

- Monitoring cold storage leaks (-30°C to 0°C).

- Studying volcanic activity (lava at 500–1000°C).

- Analyzing electronic component hotspots (50–150°C). -mwir camera

- LW thermometry avoids physical contact with targets, making it suitable for:

- Hazardous environments (e.g., radioactive sites, high-voltage areas).

- Fragile objects (e.g., historical artifacts, delicate electronics).

- High-speed processes (e.g., conveyor belt quality control without disruption).

- Many industry standards (e.g., ISO 6781 for thermography) are based on LW technology, ensuring interoperability and calibration consistency across devices.

- Example: In predictive maintenance, LW thermal maps are widely recognized for documenting equipment health over time.

| Aspect |

Long-Wave (8–14μm) |

Medium-Wave (3–5μm) |

| Ideal Temperature Range |

Low to medium (20–1000°C) |

High (800–2000°C) |

| Emissivity for Metals |

Low and variable (requires correction) |

More stable (e.g., steel ≈ 0.1–0.3) |

| Detector Cooling |

Non-cooled (microbolometers) |

Often requires cooling (e.g., InSb, MCT) |

| Typical Applications |

Building inspection, human temperature, electronics-high definition infrared camera |

Furnaces, molten metal, aerospace guidance -high speed thermal camera |

Long-wave infrared thermometry excels in low-to-medium temperature measurement, surface-level analysis, and general-purpose thermal imaging due to its high emissivity for non-metals, cost-effective sensors, and robustness in typical atmospheric conditions. Its role in safety, maintenance, and scientific research highlights its versatility in scenarios where simplicity, affordability, and non-contact operation are critical.