A vertical furnace body with continuous feeding is used to calcine limestone, so that the limestone is decomposed into quicklime CaO and carbon dioxide CO2 under high temperature conditions.

The working principle of the lime kiln mainly includes the following steps: First, the limestone is crushed and screened before entering the kiln body for calcination. During the calcination process, the fuel (such as coal, natural gas, etc.) is mixed with air and burned to generate high temperature, which decomposes the limestone into quicklime. The design of the kiln body usually includes the feeding system, combustion system, and discharge system to ensure that the limestone can be heated evenly and complete the chemical reaction.

Several common problems in the production process of lime kilns include raw burning, overburning, upward or downward movement of the calcination zone, nodules, and kiln deviation.

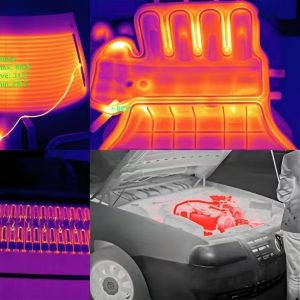

infrared thermal imaging technology improved detection efficiency, real-time monitoring, preventive maintenance, safety improvement and economic improvement

The Problem:Rotary kilns can develop invisible hot spots that lead to:✔ Sudden shutdowns costing $50,000+ per day✔ Dangerous refractory explosions✔ Wasted energy from uneven heating How Thermal Imaging Small Devices Help:These handheld tools act like "heat stethoscopes" for kilns: Spot trouble areas in 10 us from safe distances ...

Infrared thermal imaging is used to monitor the temperature distribution across various engine components, such as cylinder walls and exhaust manifolds.Infrared cameras help in detecting faults within the engine by visualizing temperature changes that occur due to mechanical failures.