Background ir camera price,thermal imaging video camera,thermal vision camera price

Background ir camera price,thermal imaging video camera,thermal vision camera priceIn the power industry, ensuring the stable operation of electrical equipment is vital for reliable power supply. However, high - voltage, high - current, and high - temperature conditions often cause component wear, overheating, and electrical connection issues. These problems not only lead to power outages and low - quality power but also pose safety risks. Traditional monitoring methods, mainly manual inspections and basic parameter checks, have significant drawbacks. Manual work is time - consuming, labor - intensive, and error - prone, while basic monitoring offers limited data.

Electrical drawer cabinets, key equipment in the power system, frequently malfunction due to issues like loose contacts, false connections, and aging. These problems increase contact resistance, cause overheating, and may trigger insulation burnout, short - circuits, and fires. Given that traditional monitoring can't meet modern safety management needs, the adoption of online detection and diagnostic technology for predictive maintenance is urgently required. As the power industry advances towards higher intelligence and stricter safety, the demand for advanced monitoring solutions is on the rise.

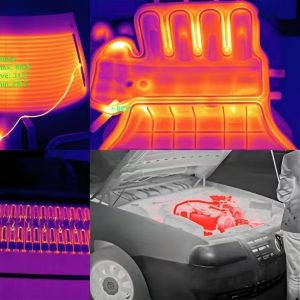

The electrical cabinet temperature monitoring system, integrated with a thermal imaging video camera, has the ability to monitor the device’s temperature online and record its changes in real time. It is designed to monitor temperature fluctuations in enclosed, elevated, or other challenging environments. The high-temperature detection and fixed-point monitoring features reduce manual inspection costs, while the equipment’s self-checking function for operational status minimizes human oversight. Capable of detecting multiple devices simultaneously, the system—backed by the thermal imaging video camera—significantly saves detection time and resources.

Product technical indicators

| prober | |

| Type of detector | Non-cooling coke plane micro-radiometric calorimeter |

| Pixel count | 256× 192 |

| Pixel spacing | 12μm |

| wavelength coverage | 8~14μm |

| Thermal sensitivity (NETD) | ≤50mk@ 25℃ |

| frame frequency | 25 Hz |

| Image processing and display | |

| Imaging time | ≤1 5 S |

| palette | A variety of palettes, including white heat, black heat, iron red, rainbow and so on |

| Contrast, brightness | Automatic / Manual |

| data format | 16Bit temperature data (full stream) |

| thermometric analysis | |

| temperature measurement accuracy | ±2° and ±2% |

| Temperature measurement range | -20-550° |

| electrical character | |

| Network standards | 100 megabits / 1 gigabit network |

| Agreement supported | UDP |

| Enter the power supply voltage | 5V~12VDC |

| CI | UART@ RS 485 (anti-control pan-tilt and camera) |

| data interface | M12 aviation plug (including power, network and RS 485 interface) |

| steady state power consumption | <2 W |

| Reverse connection protection | have |

| Overvoltage protection | have |

| enviromental parameter | |

| working temperature | -40℃~6 0℃ (-10℃~6 0℃ to ensure the accuracy of temperature measurement) |

| Storage temperature | -50℃~70℃ |

| Resistant to temperature shock | 5℃/min(-40℃~60℃) |

| vibration resistance | 4.3g, x, y, z axis for 2 hours each |

| shock resistance | Acceleration 30g, half sine wave, pulse width 6ms, and three impacts in the installation direction |

| humidity | ≤ 95% (non-condensable) |

| camera lens | |

| focal distance | Thermalization 2.0mm (F#1.1) |

| Focus on methods | hand movement |

| angle of field | 90° x 65° (horizontal field of view x vertical field of view) |

| spatial resolution | 6 mrad |

| physical characteristics | |

| outline dimension | 66 mm× 66 mm× 60.5 mm |

| classification of waterproof | IP67 |

| weight | <310 g |

| mounting hole | The bottom surface of the four sides is 2 M3 x 4 |

| client | |

| Real-time temperature display | support |

| A variety of temperature measurement objects | support |

| Alarm analysis | support |

| Video / photo / replay | support |

| SDK SDK | |

| Java runtime environment Java | Supports win32, x 64, Linux (x86/ARM) |

| data procurement | Get 16Bit temperature data (full stream) through the callback function |

infrared thermal imaging Long-distance, non-contact temperature measurement Support alarm function Real-time monitoring of kiln lining conditions

Infrared thermal imaging is used to monitor the temperature distribution across various engine components, such as cylinder walls and exhaust manifolds.Infrared cameras help in detecting faults within the engine by visualizing temperature changes that occur due to mechanical failures.