In today's competitive ceramics and industrial heating markets, proper kiln maintenance separates the professionals from the amateurs. This comprehensive guide reveals how integrating small infrared cameras, kiln cement, and kiln Portland cement into your maintenance protocol can deliver unmatched performance and reliability.

1. Small Infrared Cameras: Your Thermal Intelligence System

Modern small infrared cameras have evolved into indispensable diagnostic tools that provide:

Precision Monitoring Capabilities:

High-resolution thermal imaging with ±1°C accuracy

Wireless connectivity for remote monitoring

Automated hot spot detection algorithms

Cloud-based data storage for trend analysis

Professional Applications:

Establishing baseline thermal profiles for new kilns

Detecting refractory wear before visible damage occurs

Validating cooling curves for sensitive materials

Creating digital maintenance records for compliance

2. Kiln Cement: The Artisan's Secret Weapon

Premium kiln cement formulations now offer:

Advanced Material Properties:

Nano-enhanced particles for superior penetration

Adjustable working times from 15-90 minutes

VOC-free formulations for indoor use

Color-changing indicators for proper curing

Expert Application Techniques:

Spray applications for large surface areas

Injection methods for subsurface repairs

Custom tinting to match kiln interiors

Layered repairs for deep structural defects

3. Kiln Portland Cement: The Structural Engineer's Solution

Next-generation kiln Portland cement products feature:

Cutting-Edge Formulations:

Fiber-reinforced composites for crack resistance

Rapid-set options for emergency repairs

Low-iron variants for pure firing environments

Thermal conductivity-matched blends

Professional Repair Protocols:

Substrate preparation with diamond abrasives

Precision mixing using digital scales

Environmentally controlled curing chambers

Post-repair thermal imaging verification

The Professional Maintenance Workflow

Assessment Phase

Complete 360° infrared scan with annotated hot spots

Structural integrity evaluation

Material compatibility analysis

Precision Repair Phase

Targeted kiln cement applications

Custom-formulated Portland cement repairs

Real-time thermal monitoring during curing

Validation Phase

Post-repair thermal performance testing

Documentation for maintenance records

Scheduled follow-up inspections

Pro Tips from Industry Leaders

Establish a thermal fingerprint for your kiln when new

Create custom cement blends for your specific firing cycles

Implement predictive maintenance algorithms

Develop staff certification programs for repair techniques

Why Professionals Choose This Approach

30-50% reduction in unplanned downtime

15-25% improvement in energy efficiency

2-3x extension in refractory life

Consistent, repeatable firing results

Compliance with industry best practices

For facilities ready to implement professional-grade kiln maintenance programs, our team offers:

On-site thermal imaging services

Custom cement formulation development

Technician training and certification

Maintenance program design

Remember: In industrial heating applications, the most sophisticated operations aren't those with the newest equipment - they're those who have mastered the art and science of maintenance with small infrared cameras, kiln cement, and kiln Portland cement.

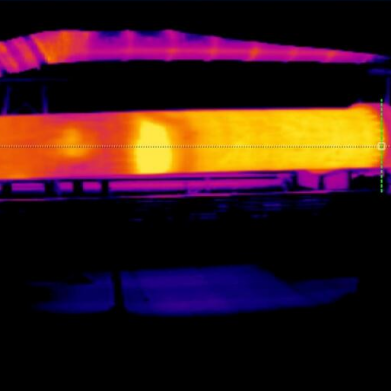

Critical Areas to Monitor: Furnace walls (hot spots = thinning) Conveyor bearings (heat = failing soon) Ladles (uneven heating risks cracks) Why This Beats Old Methods:Old way:✖ Shut down for inspections✖ Guess based on experience New way with thermal imaging small tech:✓ Scan during operation✓ See exact trouble spots Cost-Savin...

Read More

In today's rapidly evolving industrial landscape, kiln operators face increasing pressure to maximize uptime while minimizing costs. This paradigm shift has given rise to a new era of predictive maintenance powered by three game-changing technologies: small infrared cameras, kiln cement, and kiln Portland cement. Let's examine how th...

Read More