Maintaining your kiln properly ensures consistent results and prevents costly damage. Whether you're a ceramic artist or industrial operator, understanding proper unloading and maintenance techniques is crucial. This guide highlights three essential components for optimal kiln performance: small infrared cameras, kiln cement, and kiln Portland cement.

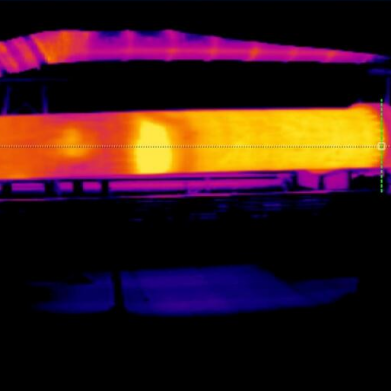

Before unloading, always verify the kiln has cooled sufficiently. A small infrared camera provides accurate, non-contact temperature readings, allowing you to:

Identify hot spots that might cause thermal shock

Ensure safe handling conditions for operators

Prevent damage to sensitive ceramic pieces

Regular use of a small infrared camera during cooling cycles significantly improves safety and prevents accidents.

Repeated heating cycles inevitably cause small cracks around doors and joints. Applying kiln cement offers these benefits:

Restores airtight seals for better temperature control

Reduces heat loss and improves energy efficiency

Extends the lifespan of kiln components

For best results, inspect and apply kiln cement after each cooling cycle, paying special attention to door seals and observation ports.

When facing more significant damage like cracked firebricks or refractory surfaces, kiln Portland cement provides durable solutions:

Withstands extreme temperatures better than standard cement

Creates long-lasting repairs for kiln interiors

Maintains structural integrity through multiple firing cycles

Always mix kiln Portland cement according to manufacturer specifications and allow proper curing time before resuming operations.

Monitor cooling with a small infrared camera before every unloading

Seal minor gaps immediately using kiln cement

Repair structural damage with kiln Portland cement as needed

Document all maintenance for future reference

By incorporating these tools into your regular maintenance routine, you'll achieve:

Safer working conditions

More consistent firing results

Reduced energy costs

Extended equipment lifespan

For additional resources on kiln maintenance best practices, visit our technical support section or contact our expert team. Remember - proactive care using small infrared cameras, kiln cement, and kiln Portland cement is the most cost-effective way to maintain peak kiln performance.

In today's rapidly evolving industrial landscape, kiln operators face increasing pressure to maximize uptime while minimizing costs. This paradigm shift has given rise to a new era of predictive maintenance powered by three game-changing technologies: small infrared cameras, kiln cement, and kiln Portland cement. Let's examine how th...

Read More

In the world of kiln operation, success depends equally on artistic vision and technical precision. Mastering three key maintenance tools - small infrared cameras, kiln cement, and kiln Portland cement - can elevate your craft while protecting your investment. Let's explore how these solutions work together to create a maintenance sy...

Read More