In the world of kiln operation, success depends equally on artistic vision and technical precision. Mastering three key maintenance tools - small infrared cameras, kiln cement, and kiln Portland cement - can elevate your craft while protecting your investment. Let's explore how these solutions work together to create a maintenance symphony.

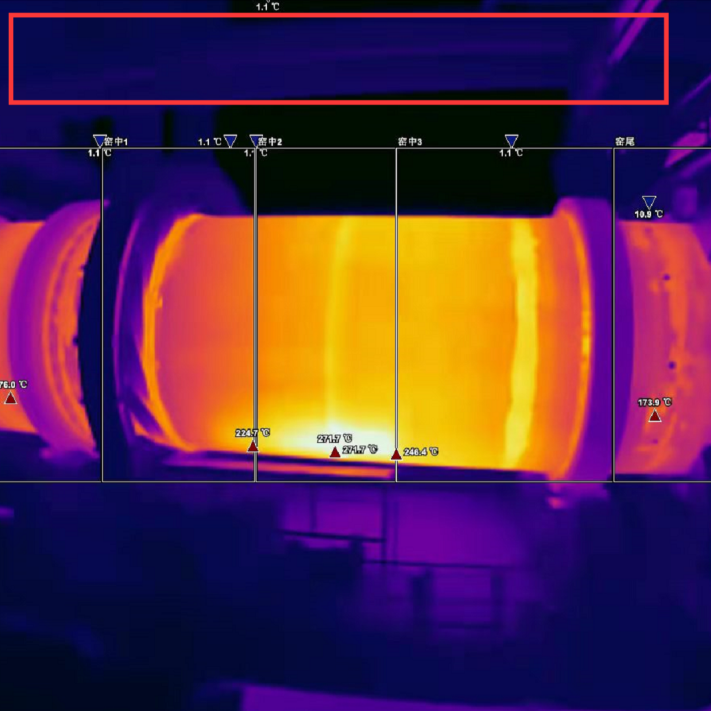

1. The Diagnostic Power of Small Infrared Cameras

Modern small infrared cameras have become the stethoscopes of kiln operators, offering:

Real-time thermal imaging for precise temperature assessment

Non-invasive scanning of hard-to-reach areas

Historical temperature data logging

Early warning system for potential hot spots

Professional applications include:

Verifying even heat distribution during cooling cycles

Creating thermal maps for process optimization

Documenting temperature profiles for quality control

Ensuring safe working conditions for maintenance crews

2. Kiln Cement: The Flexible Protector

Kiln cement acts as both shield and sealant, providing:

Customizable viscosity for different application methods

Thermal expansion matching most refractory materials

Chemical resistance to kiln atmospheres

Long-term adhesion without cracking

Advanced application techniques:

Layered applications for deep cracks

Precision nozzle delivery for tight spaces

Custom blends for specialty kiln types

Color-coded formulations for maintenance tracking

3. Kiln Portland Cement: The Structural Backbone

When structural integrity is paramount, kiln Portland cement delivers:

Engineered particle size distribution for optimal packing

Controlled setting times for different repair scenarios

Thermal shock resistance through microstructural design

Compatibility with various reinforcement materials

Professional-grade repairs involve:

Pre-repair thermal imaging analysis

Custom aggregate blends for specific applications

Controlled curing environments

Post-repair performance verification

Integrated Maintenance Protocol

Diagnostic Phase (Infrared Imaging)

Full thermal scan of kiln interior

Hot spot identification and documentation

Structural stress point analysis

Preventative Maintenance (Kiln Cement)

Targeted sealing of vulnerable joints

Thin protective coatings for high-wear areas

Expansion joint maintenance

Structural Rehabilitation (Kiln Portland Cement)

Damage assessment and material selection

Precision mixing and application

Controlled curing process

Final quality inspection

Advanced Professional Tips

Create a digital maintenance log with thermal images

Develop custom cement blends for your specific kiln

Implement predictive maintenance schedules

Train staff in advanced application techniques

By mastering the use of small infrared cameras, kiln cement, and kiln Portland cement, professionals gain:

Unparalleled process control

Reduced unscheduled downtime

Extended equipment lifespan

Consistent, repeatable results

Competitive advantage in quality and efficiency

For professionals ready to take their kiln maintenance to the next level, our technical team offers advanced training programs and custom consultation services. Remember - in kiln operation, the difference between good and great often lies in the details of maintenance.

LASER Photonics China 2025: A new chapter of optoelectronic technology innovation and global cooperation From March 11 to 13, 2025, the most influential event in Asia's optoelectronics industry, LASER Photonics China, will be held in Shanghai New International Expo Center. As the flagship exhibition in China's laser, optics and optoe...

Read More

Maintaining your kiln properly ensures consistent results and prevents costly damage. Whether you're a ceramic artist or industrial operator, understanding proper unloading and maintenance techniques is crucial. This guide highlights three essential components for optimal kiln performance: small infrared cameras, kiln cement, and kil...

Read More