Backaground

As an important container for transporting molten steel and conducting secondary metallurgical reactions in the converter and continuous casting sections, the management and scheduling of the ladle play an important role in optimizing the operation and energy saving and consumption reduction of the steel plant. The ladle consists of a barrel, a lining, a nozzle opening and closing device, and a breathable brick.

The main function of the ladle is to receive the molten steel and part of the slag flowing out of the tapping door of the primary steelmaking furnace (converter or electric furnace). The molten steel can be calmed for a period of time to adjust the temperature of the molten steel, even the composition, and float the non-metallic inclusions in the molten steel. At the same time, the steel flow is opened and closed during the pouring process to control the flow of molten steel and liquid steel to ensure smooth pouring.

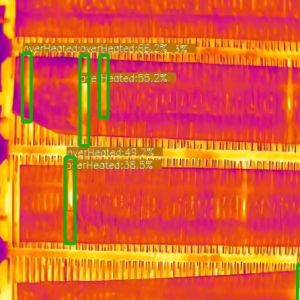

In recent years, major accidents caused by safety hazards such as overheating of molten steel (iron) piercing the ladle, severe wear of the ladle lining, and fatigue damage in the ironmaking and steelmaking processes of the metallurgical industry have frequently occurred, posing a serious threat to production safety.

Practice has shown that the initial defects of the ladle lining will gradually develop from point to surface until complete failure. When the lining peels off in the early stage, the temperature of the peeling point area will be abnormally high, and the temperature of the defective area will be significantly higher than other locations. Therefore, the use of infrared thermal imagers to achieve online rapid detection and diagnosis can timely detect abnormal temperature changes of equipment, locate defective parts, and promptly avoid safety accidents to ensure normal production operations.

Advantagies

In the world of kiln operation, success depends equally on artistic vision and technical precision. Mastering three key maintenance tools - small infrared cameras, kiln cement, and kiln Portland cement - can elevate your craft while protecting your investment. Let's explore how these solutions work together to create a maintenance sy...

The Problem:Rotary kilns can develop invisible hot spots that lead to:✔ Sudden shutdowns costing $50,000+ per day✔ Dangerous refractory explosions✔ Wasted energy from uneven heating How Thermal Imaging Small Devices Help:These handheld tools act like "heat stethoscopes" for kilns: Spot trouble areas in 10 us from safe distances ...

Optimize the thermal efficiency of the sintering process, reduce energy consumption, adjust the amount and distribution of solid fuel according to the temperature distribution of the material layer, avoid heat waste caused by excessive fuel or incomplete sintering caused by insufficient fuel, and reduce fuel consumption per ton of o...

HJK Professional customized infrared thermal imaging technology with higher fault detection accuracy, can accurately locate each anode and cathode plate, also accure detected the short-circuited plate greatly improving the detection efficiency.