Background

The P-S converter is an important equipment for blister copper refining. Through secondary oxidation reactions in the slag-making and copper-making stages, Fe and S in the copper matte liquid are removed to form blister copper.

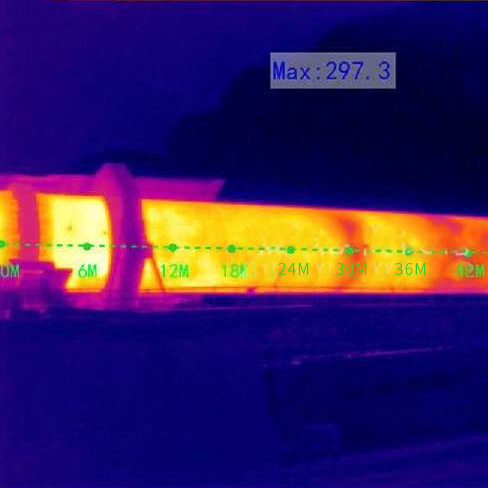

During the two processes of blowing, the reactions that occur are almost all exothermic reactions, which will release a large amount of heat. Therefore, the temperature of the outer wall of the furnace body is sometimes too high. In addition, the gas and copper matte liquid (as well as the white matte formed later) entering the furnace from the tuyere will scour the refractory materials on the inner wall of the furnace. The temperature of some refractory materials lost or missing parts will be higher, sometimes reaching more than 400 degrees. At the same time, during the blowing process, due to the characteristics of pyrometallurgy, there will be splashes in the blowing process that will adhere to the water jacket and fall behind the furnace after cooling. In order to avoid the damage to the tuyere by falling pieces, a 20mm thick steel plate is added to the center area of the tuyere to protect the tuyere from large pieces. The newly added protective plate will affect the temperature measurement of the furnace body. The protective plate must be modified to measure the corresponding outer wall of the furnace. In addition, the tuyere hose will also block the furnace wall, but the outer wall temperature can be measured through the gap between the hoses.

Product Description

The HIRDA-PS P-S converter infrared thermal imaging intelligent monitoring system is a cutting-edge solution designed for temperature monitoring in high-temperature metal smelting furnaces. At its core, the system integrates a high-temperature thermal infrared camera (capable of precise heat detection) and a complementary thermo camera module, both serving as the primary sensors for real-time temperature acquisition. Paired with an electric control box, an algorithm server, and client management software, the system enables centralized monitoring and management of on-site equipment. Leveraging a digital transmission network, it seamlessly executes functions such as data collection, thermal analysis, high-temperature point positioning, and automatic alarm triggering—all driven by the advanced capabilities of its thermal camera suite to ensure accurate and timely insights into the P-S converter wall temperature.

Advantages

When working with kilns, proper cooling and maintenance are crucial for safety and efficiency. One critical step is kiln cooling and unloading, often referred to as "kiln unloading" or "kiln discharge." In this process, monitoring temperature and sealing any gaps are key to preventing heat loss and structural damage. Here’s how small...

Read More

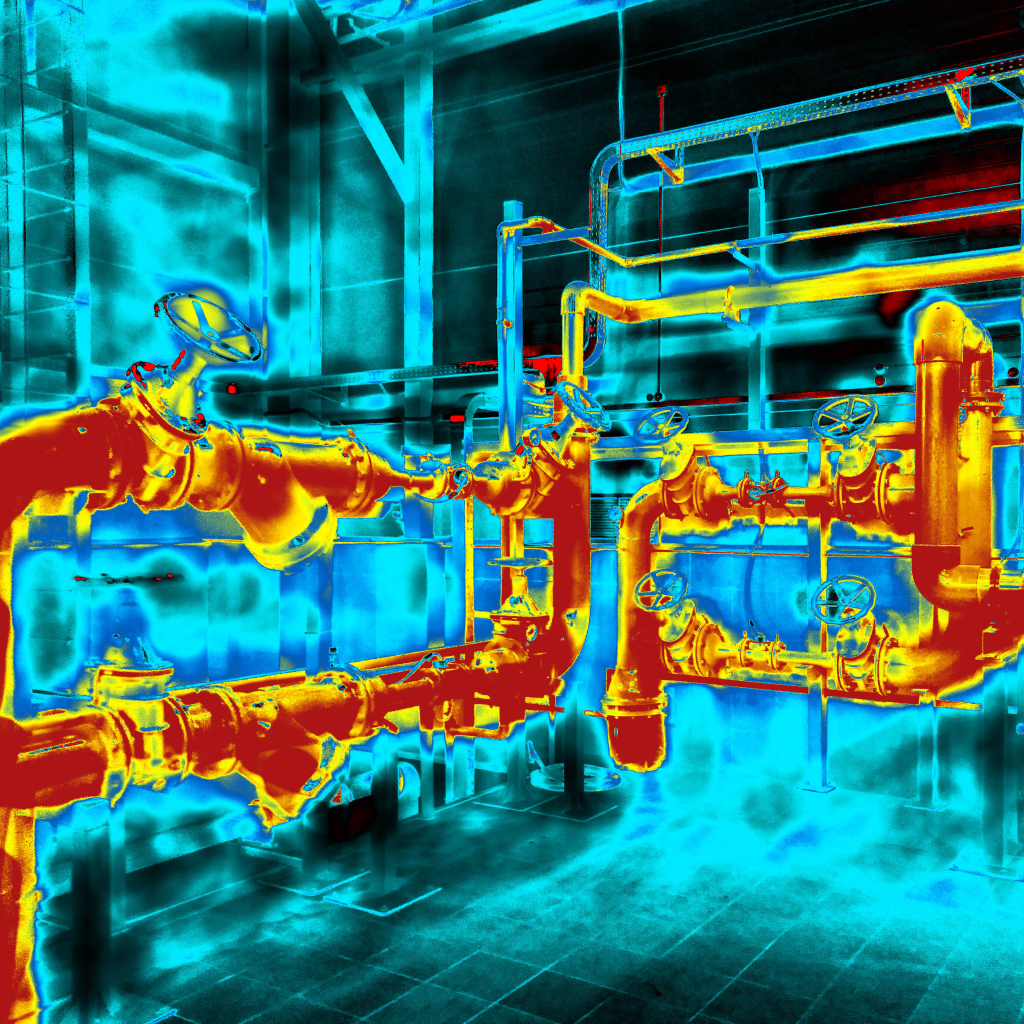

Invisible Dangers Thermal Cameras Reveal:✔ Gas leaks (shows as "cold clouds")✔ Tank leaks (wet areas look different)✔ Pump failures (abnormal heat patterns) Why Workers Love These Tools: Thermal imaging small cameras fit in tool belts No need to shut down equipment Takes 1/10th the time of old inspection methods Case Study:A refi...

Read More