Background

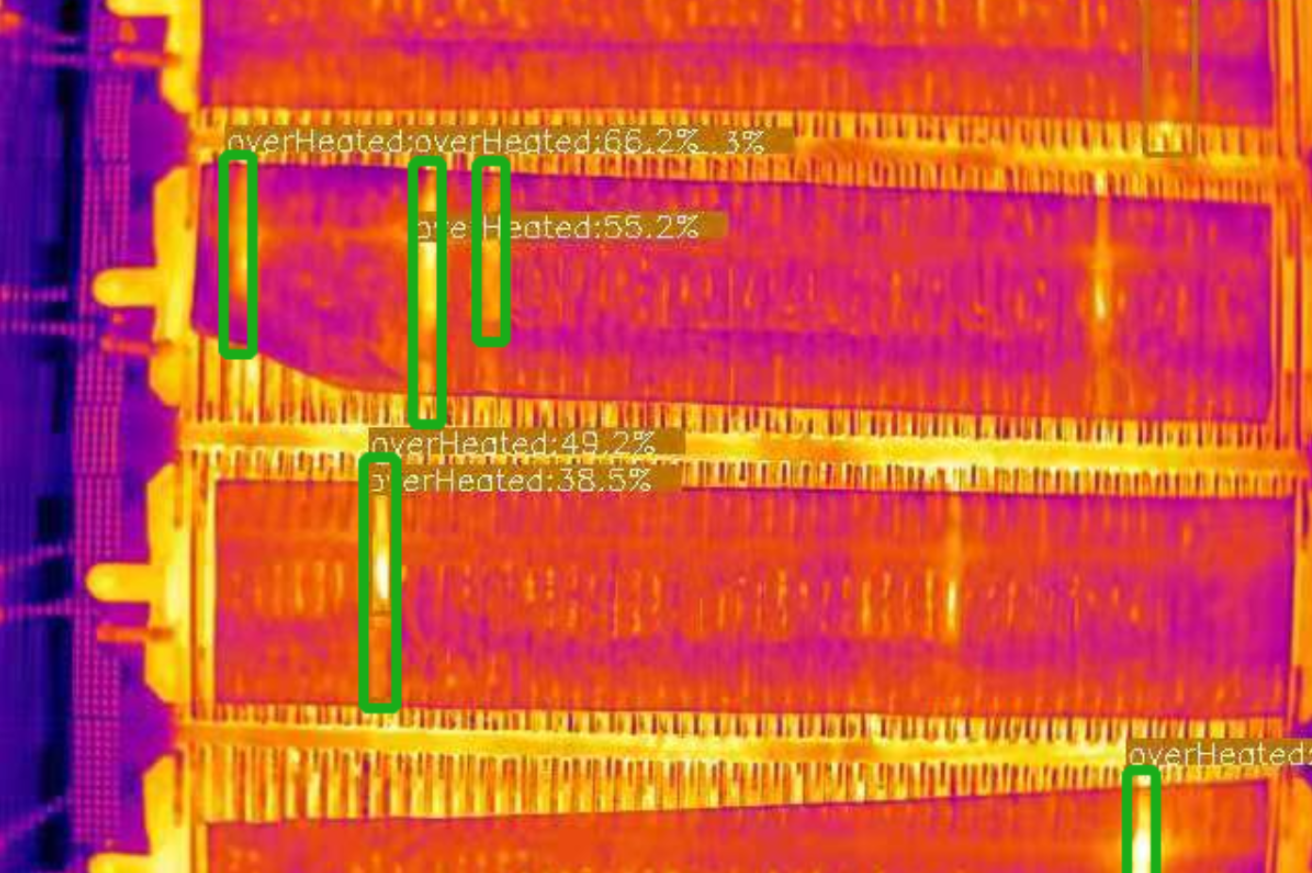

During the accumulation of cathode copper in the electrolytic cell, local short circuits sometimes occur, which will cause a large amount of power loss and high temperature, seriously affecting the normal production of cathode copper. At present, manual detection and other methods are generally used to detect the occurrence of short circuits, which have problems such as low detection efficiency, high labor intensity of workers, and harm to health. Therefore, timely detection and accurate positioning of the short circuit fault of the plate in the electrolytic cell has become one of the important conditions for electrolytic copper production. It is related to power efficiency and product quality. The traditional operation method is inefficient and has safety hazards. After a short circuit fault occurs in the plate of the electrolytic cell, the temperature rises sharply. By using thermal cameras to fully monitor the electrolytic cell, the short-circuited plate can be accurately detected and located, greatly improving the detection efficiency.

Advantagies

In the world of kiln operation, success depends equally on artistic vision and technical precision. Mastering three key maintenance tools - small infrared cameras, kiln cement, and kiln Portland cement - can elevate your craft while protecting your investment. Let's explore how these solutions work together to create a maintenance sy...

In an era where precision and efficiency define industrial success, forward-thinking kiln operators are revolutionizing their maintenance strategies. By harnessing the power of small infrared cameras, kiln cement, and kiln Portland cement, modern facilities are achieving unprecedented levels of performance and reliability. This artic...

3 Big Benefits: Spot furnace problems before they ruin batches Save energy by finding heat leaks Improve quality with even heating Real-World Example:A cement plant using infrared cameras thermal imaging found a hidden hot spot that could have caused a 3-week shutdown. The fix took 2 days. How It Works in Practice: Scan electrolytic...