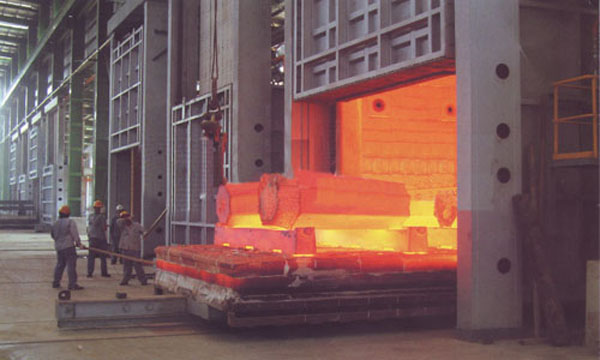

As an important heating equipment in the steel rolling process, the heating furnace not only affects the production cost of steel rolling, but also affects the product quality of steel rolling. Infrared thermal imagers can detect defects such as cracks, thinning, and shedding of the furnace lining, which is of great significance to ensure the safety and long-term operation of the equipment.

The working principle of the heating furnace is mainly to heat the metal by generating eddy currents in the metal through electric current. Specifically, the induction heating furnace uses medium-frequency current to generate eddy currents through the induction coil. These eddy currents generate heat when flowing inside the metal, thereby heating the metal.

The heating furnace may encounter a variety of problems during use, mainly including unstable temperature, poor heating uniformity, too long heating time, motor or mechanical failure, poor exhaust valve, excessive excess air coefficient or high oxygen content, high CO content or too low oxygen content, rising exhaust temperature, and ash, salt, and scaling on the heated surface.

Infrared thermal imaging camera can detect defects such as cracks, thinning, and shedding of the furnace lining, which is of great significance to ensure the safety and long-term operation of the equipment.

Camera with infrared technology measures the surface temperature of objects in a non-contact manner, achieving precise temperature control of heating furnaces and improving equipment maintenance efficiency. In production, this technology improves product quality and production efficiency, reduces maintenance costs, and has broad application prospects.

Thermal image camera technology is a technology that can detect and measure the surface temperature distribution of objects. It captures the infrared radiation emitted by the object and converts the received information into a thermal image that we can intuitively understand. The biggest feature is that it can monitor the temperature of objects in real time at a long distance without contact.

The application of infrared thermal imaging technology in heating furnaces has triggered a technological innovation and changed the way we observe and manage heating furnaces. This technology enables us to monitor the temperature inside the heating furnace in an all-round and non-dead angle manner, thereby achieving more precise temperature control, optimizing the production process, and improving product quality. This transformation not only improves production efficiency, but also provides the possibility of improving product quality.

In today's competitive ceramics and industrial heating markets, proper kiln maintenance separates the professionals from the amateurs. This comprehensive guide reveals how integrating small infrared cameras, kiln cement, and kiln Portland cement into your maintenance protocol can deliver unmatched performance and reliability. 1. Smal...