Background

In the continuous casting process, production parameters like the speed control of the continuous casting machine's billet drawing roller and fixed-length cutting control are highly sensitive to billet temperature. During billet pulling, excessively high temperatures can prevent full solidification, causing final solidification time to fall far below the straightening roller and local chain breakage rectification period—potentially leading to quality degradation and billet breakage. Conversely, overly low temperatures can cause premature solidification, making the billet difficult to plasticize and shortening production machinery lifespan. Thus, billet temperature remains a critical parameter in continuous casting, with accurate monitoring reliant on equipment like IR cameras. While considering ir camera price as part of operational costs, investing in reliable temperature measurement ensures process stability and avoids costly production disruptions.

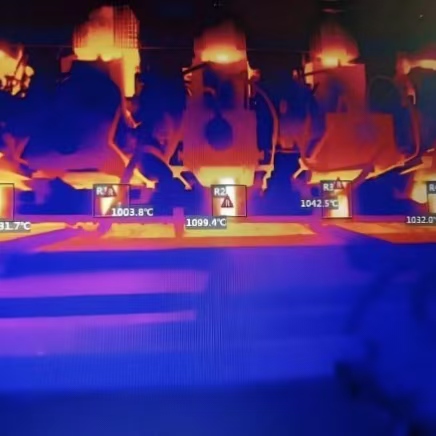

Thermal imaging video camera is a device that converts the target temperature distribution into a visible image and an accurate temperature value by detecting the infrared radiation of the target and performing signal processing, photoelectric conversion and other means. The infrared thermal imaging thermometer accurately quantifies the actual detected heat and images the entire target in real time in the form of a surface, so it can accurately identify the real-time temperature of multi-track billets. The operator obtains the real-time temperature of the billet through the image color and hot spot tracking display function displayed on the screen, and strictly analyzes it, thereby reflecting high efficiency and high accuracy in confirming the problem.

The thermal vision camera price uses advanced non-contact infrared detection technology to quickly, accurately, conveniently and intuitively display the distribution of the surface temperature field of the measured object and measure the surface temperature of the object. It can quickly test the surface temperature reading of the object without direct contact with the surface of the measured object, and can reliably measure the surface temperature of hot, dangerous or difficult-to-reach objects. The infrared thermal imager has a very fast measurement speed and can intuitively and continuously test the temperature changes on the surface of the object.

Advantagies

HJKIR infrared solutions with electrical cabinet temperature monitoring system has strong penetration of smoke, and can be used in a wide range of ambient temperature. Offers multiple equipment detection at the same time, saving the detection cost.

In the world of kiln operation, success depends equally on artistic vision and technical precision. Mastering three key maintenance tools - small infrared cameras, kiln cement, and kiln Portland cement - can elevate your craft while protecting your investment. Let's explore how these solutions work together to create a maintenance sy...

In today's competitive ceramics and industrial heating markets, proper kiln maintenance separates the professionals from the amateurs. This comprehensive guide reveals how integrating small infrared cameras, kiln cement, and kiln Portland cement into your maintenance protocol can deliver unmatched performance and reliability. 1. Smal...