Benefits of infrared protective housing

Here are the key benefits of infrared protective housing:

-

Impact & Vibration Resistance

Constructed from high-strength materials (e.g., aluminum alloy, stainless steel, or engineering plastics), infrared protective housings shield sensitive infrared equipment (such as thermal cameras or pyrometers) prevent security thermal from mechanical shocks, dust, and liquid splashes (e.g., metal debris or oil in industrial environments). This extends the equipment’s service life.

Applications: Factory production lines, outdoor inspections, construction sites, and other high-vibration or high-risk environments.

-

Environmental Durability

Designed with waterproof and dustproof features (meeting IP65/IP68 protection ratings), these housings prevent rain, moisture, and contaminants from entering the internal circuitry. This avoids issues like lens fogging or detector damage due to humidity.

They also withstand extreme temperatures (-40°C to 85°C or higher), ensuring stable performance in harsh climates (e.g., near high-temperature furnaces or in subzero outdoor conditions).

-

High Infrared Transmittance

Equipped with specialized infrared-transparent windows (made of materials like germanium, silicon, or zinc selenide), protective housings minimize signal loss by allowing optimal transmission of infrared radiation (e.g., in the 3–5μm or 8–14μm bands). This preserves the accuracy of temperature measurements and thermal imaging.

-

Thermal Stability & Anti-Interference

The housing’s thermal design reduces heat distortion or mechanical stress that could affect optical alignment. Some models include built-in cooling/heating systems (e.g., fans, Peltier elements) to maintain a stable internal temperature, preventing measurement errors caused by environmental temperature fluctuations.

Additionally, anti-reflective coatings on the windows reduce glare from ambient light, enhancing the clarity of thermal data.

-

Adaptability to Diverse Scenarios

Many housings feature adjustable mounts, pan-tilt mechanisms, or modular designs, enabling easy integration with robotic systems, drones, or fixed industrial installations. This flexibility supports applications in surveillance, predictive maintenance, and automated quality control.

-

Reduced Maintenance & Replacement Costs

By shielding equipment from wear and tear, protective housings significantly lower maintenance frequency (e.g., lens cleaning, circuit repairs) and reduce the need for premature equipment replacement. This is particularly valuable in hard-to-reach or hazardous locations (e.g., chemical plants, high-voltage areas).

-

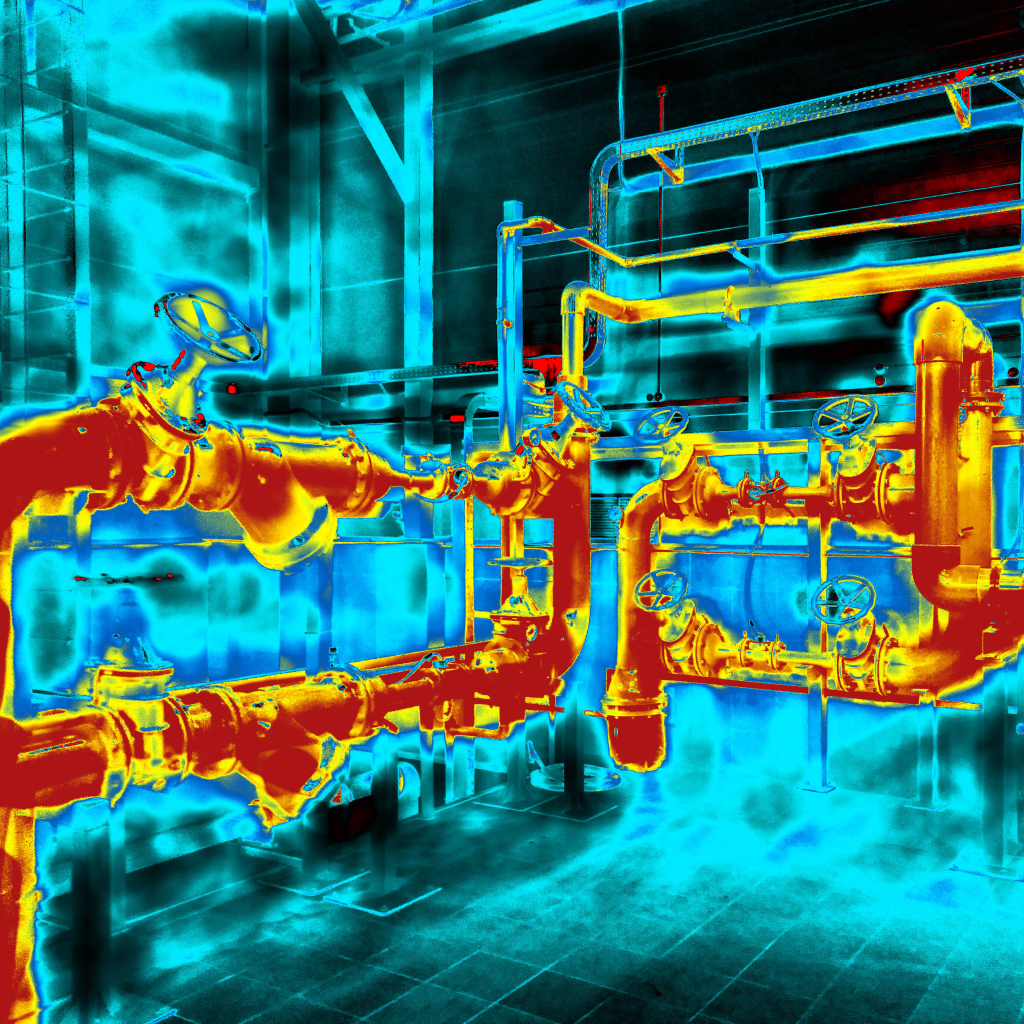

Hazard Mitigation

In explosive or corrosive environments (e.g., oil refineries, chemical facilities), explosion-proof or corrosion-resistant housings (certified to standards like ATEX or IECEx) prevent sparks or material degradation, ensuring compliance with safety regulations and minimizing risks of fire or equipment failure.

-

Long-Term Reliability

For critical infrastructure (e.g., power plants, railways), protective housings ensure continuous, uninterrupted operation of infrared monitoring systems, supporting early detection of faults (e.g., overheating components) and preventing costly downtime.

- By isolating sensitive components from harsh environmental factors (e.g., UV radiation, salt spray, or abrasive particles), protective housings slow down the degradation of lenses, detectors, and electronic parts. This extends the operational lifespan of infrared equipment, providing a higher return on investment (ROI) over time.

In summary, infrared protective housings balance rugged physical protection with optical precision, making them essential for maintaining the reliability, accuracy, and longevity of infrared systems in challenging industrial, outdoor, and hazardous environments.