A handheld thermal camera offers numerous advantages that make it a valuable tool across various fields. One of the key benefits is its portability. Unlike larger, stationary thermal imaging systems, a hand held thermal device can be easily carried and used on - site, enabling quick and convenient inspections in diverse environments. Whether you're checking for heat leaks in a building, monitoring electrical equipment in an industrial facility, or conducting search and rescue operations in the outdoors, its compact size allows you to take it wherever the task requires.

Another significant advantage is non - contact temperature measurement. A thermal imaging camera handheld can detect infrared radiation emitted by objects from a distance, providing temperature readings without the need for physical contact. This is especially useful when dealing with high - voltage electrical components, hazardous materials, or extremely hot surfaces. It not only ensures the safety of the operator but also prevents any potential damage or interference to the objects being measured.

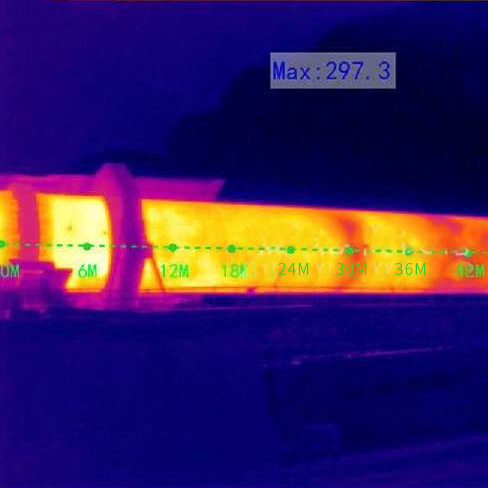

The handheld thermal camera also offers real - time imaging capabilities. It can instantly convert infrared radiation into visible thermal images, allowing users to observe heat patterns and temperature variations in real - time. This immediate feedback is crucial for identifying issues promptly, such as hotspots in electrical circuits that could indicate impending failures, or uneven heating in industrial processes that might affect product quality.

Moreover, hand held thermal devices can operate effectively in low - light or complete darkness. Since they rely on detecting infrared radiation rather than visible light, they can provide clear thermal images even in the absence of ambient light. This makes them ideal for night - time surveillance, search and rescue missions during the night, or inspections in poorly lit areas, where traditional visual inspection methods would be ineffective.

Finally, many thermal imaging camera handheld models come with additional features like image storage, temperature measurement tools, and the ability to overlay thermal and visible light images. These features enhance the functionality of the device, enabling users to document findings, analyze data later, and get a more comprehensive understanding of the situation. Overall, the combination of portability, non - contact measurement, real - time imaging, low - light operation, and advanced features makes handheld thermal cameras an indispensable tool for a wide range of applications.