Project background

Project background

As an important part of the metallurgical industry, the temperature measurement of molten iron is completed by manual observation, thermocouples, and temperature guns. The working environment is harsh, and the temperature of molten iron needs to be measured many times. The labor intensity is high, the number of temperature measurements is small, and only 1 to 3 times are measured each time the iron is tapped. Continuous temperature measurement cannot be achieved. In addition, thermocouples are consumables, with high costs and relatively backward operation methods. The fluctuation of workers' operation norms makes the monitoring of molten iron temperature not accurate enough, and cannot reflect the temperature situation and change trend of the entire iron tapping process. In particular, the environment in front of the blast furnace is harsh, high temperature, and dusty, which is very dangerous. Since the ironmaking process in the blast furnace is fully enclosed, it is difficult to measure the temperature directly in the furnace. We need to understand and control the temperature state of molten iron through external temperature measurement. If the temperature of molten iron is too low, it will affect the smooth operation of the blast furnace. For a long time, it will cause serious consequences such as furnace body adhesion, abnormal furnace shape, abnormal furnace condition, and endangerment of safe production. In addition, molten iron temperature detection provides the most direct and effective detection method for low-silicon smelting. On the premise of ensuring sufficient physical temperature, the silicon content is reduced as much as possible, thereby reducing the coke ratio, which is beneficial to the steelmaking process. The temperature of molten iron is of great significance to the operation of blast furnaces, so it is necessary to establish a safe and intelligent continuous temperature measurement system for the taphole.

Solution

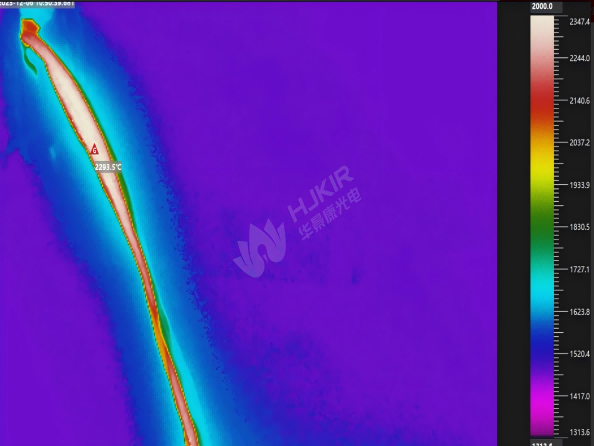

Our unit has developed a new type of continuous temperature measurement system for molten iron, leveraging thermal imaging cameras to directly measure the temperature of the iron flow at the taphole during tapping. This eliminates temperature drop and uniformity issues caused by the main ditch and slag skimmer, using an infrared thermography camera to more directly and accurately represent the furnace’s physical heat state and change process. Equipped with thermal cameras, the system features strong anti-smoke interference, long measurement distance, flexible target alignment, and precise readings. Molten iron temperature data is transmitted via signal lines to a host computer in the main control room, where a specialized program collects, processes, displays, and stores the information.

Advantagies

infrared thermal imaging technology Real-time monitoring and fault location efficiency Safety assurance

HJKIR Infrared power plant products solutions offers PSGMT490 dual-spectrum head infrared camera with 255 preset bits. Widely used in substation, power distribution room, factory inspection and other scenarios. Offers self-test function, manual control of multi-level speed adjustable functions.

HJKIR application with the integration of infrared (IR) thermal imaging cameras, enhancing quality control and efficiency in welding processes.