thermal imaging video camera Revolutionize Automotive Welding Quality Control,the automotive industry is undergoing a technological transformation with the integration of infrared (IR) thermal imaging cameras, enhancing quality control and efficiency in welding processes. These cameras provide real-time temperature monitoring, enabling the detection of defects and ensuring reliable welds for both plastic and metal components

Solution Description:

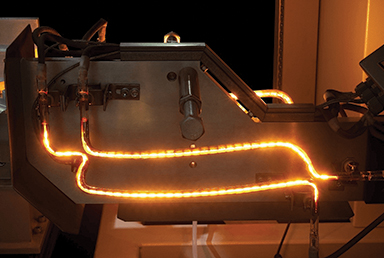

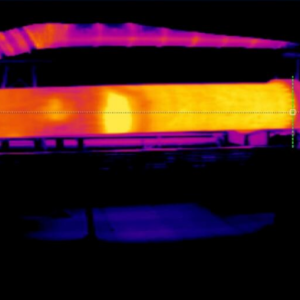

Infrared cameras capture temperature distributions across welding surfaces, offering a comprehensive view compared to traditional spot measurement systems like pyrometers. Companies like Optris and DYT offer advanced infrared camera solutions that can be seamlessly integrated into existing automotive production lines without significant cost overruns. These cameras, with thermal vision camera price influencing model selection, operate within specific spectral ranges (e.g., 8 to 14 micrometers for plastics) and can be integrated via software development kits (SDKs). Some cameras, like the XIR-1800 (priced to suit industrial needs), provide detailed imaging of metal joining, capturing key melting and transition temperatures. These systems facilitate real-time temperature feedback and welding parameter adjustments, essential for automated welding. An infrared camera set at a fixed position along the production line can repeatably and accurately illustrate the thermal patterns and gradients.

Improved Welding Quality: Precise temperature control ensures each weld meets optimal conditions, reducing defects and structural problems.

Enhanced Efficiency: Non-contact detection speeds up quality inspection, reducing the need for rework and manual checks.

Reduced Defect Rates: Real-time monitoring allows for timely identification and correction of issues, minimizing defective products.

Increased Safety: Prevents equipment overheating and material damage, ensuring safer welding operations.

Intelligent Production: Integration with automation systems promotes intelligent manufacturing

Comprehensive Coverage: Unlike spot measurement systems, infrared cameras capture temperature distribution across the entire welding surface

Real-Time Monitoring: Provides a real-time snapshot of the weld, enabling immediate adjustments to maintain weld quality.

Early Detection: Identifies temperature variations early, allowing engineers to correct

errors and prevent defective products

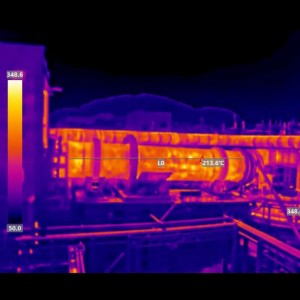

Every kiln operator knows that proper maintenance makes the difference between consistent results and costly downtime. In this guide, we'll explore how three specialized tools - small infrared cameras, kiln cement, and kiln Portland cement - can transform your maintenance routine and keep your kiln operating at peak efficiency. 1. Pr...

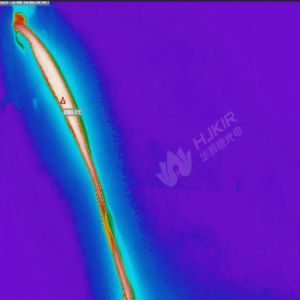

HJKIR developed a new type of continuous temperature measurement system for molten iron, which can directly measure the temperature of the iron flow at the taphole during tapping and more directly and accurately represent the state and change process of the physical heat of the furnace. At the same time, it has the outstanding characteristics of...

In today's rapidly evolving industrial landscape, kiln operators face increasing pressure to maximize uptime while minimizing costs. This paradigm shift has given rise to a new era of predictive maintenance powered by three game-changing technologies: small infrared cameras, kiln cement, and kiln Portland cement. Let's examine how th...