What are the application scenarios of infrared protective housing?

Here are the primary application scenarios of infrared protective housing:

- High-Temperature Environments

Used in steel mills, foundries, and glass factories to protect infrared cameras or pyrometers near furnaces, kilns, or casting lines (e.g., monitoring molten metal temperatures without equipment damage from radiant heat or sparks).

- Harsh Industrial Settings

Deployed in automotive assembly lines, chemical plants, or food processing facilities to shield equipment from dust, oil, steam, or mechanical vibrations (e.g., quality control of hot components or leak detection in pipelines).

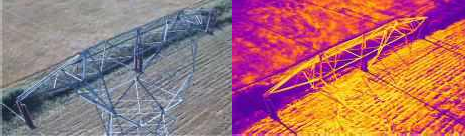

- Power Plants (Thermal, Nuclear, Renewables)

Protects infrared sensors monitoring turbine generators, transformers, or solar panel arrays from extreme temperatures, humidity, or corrosive gases (e.g., early detection of overheating in electrical connections).

- Substations & High-Voltage Systems

Explosion-proof housings (e.g., ATEX-certified) are used in hazardous zones to safely monitor switchgear, circuit breakers, or battery energy storage systems (BESS) without risk of spark-induced explosions.

- Aviation & Aerospace

Installed on aircraft engines or ground support equipment to withstand jet exhaust heat, icing, or debris (e.g., thermal imaging of engine components during pre-flight inspections).

- Railways & Maritime

Used on locomotives, ship engines, or cargo containers to monitor brake systems, electrical cabinets, or refrigeration units in harsh weather (e.g., saltwater corrosion resistance for marine applications).

- Autonomous Vehicles & Robotics

Enables ruggedized thermal cameras on AGVs (automated guided vehicles) or drones for obstacle detection, warehouse inventory scanning, or disaster response in dusty/foggy conditions.

- Offshore Platforms & Refineries

Corrosion-resistant and explosion-proof housings protect infrared equipment in environments with salt spray, flammable gases, or volatile chemicals (e.g., detecting pipeline leaks or hotspots in storage tanks).

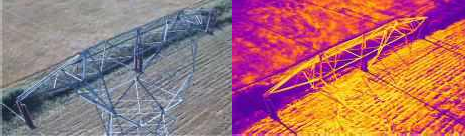

- Pipeline Surveillance

Mounted on drones or fixed towers for long-range thermal monitoring of buried pipelines, identifying leaks or insulation failures in remote or ecologically sensitive areas.

- Firefighting & Emergency Response

Heat-resistant housings (e.g., ceramic-coated) for thermal imaging cameras used in wildfires or structural fires, allowing firefighters to navigate smoke-filled environments while protecting equipment from flames and debris.

- Perimeter Security

Outdoor-rated housings with IP68 protection deploy thermal cameras for 24/7 surveillance in airports, prisons, or borders, ensuring reliable operation in rain, snow, or extreme temperatures (e.g., detecting intruders in low-light conditions).

- Laboratories & Testing Facilities

Shield infrared spectrometers or imaging systems from dust, moisture, or electromagnetic interference during material science experiments, atmospheric research, or semiconductor testing.

- Environmental Monitoring

Used in weather stations, polar expeditions, or volcanic monitoring to withstand extreme cold, high winds, or acidic gases (e.g., measuring geothermal activity with ruggedized thermal sensors).

- ** Sterile & Controlled Environments**

Stainless steel or antimicrobial-coated housings protect infrared thermometers or imaging systems in operating rooms, cleanrooms, or pharmaceutical production lines, preventing contamination while monitoring temperature-sensitive processes (e.g., vaccine storage).

- Combat & Surveillance Systems

Military-grade housings (e.g., MIL-STD-810G compliant) for thermal sights, drone payloads, or tank-mounted sensors, ensuring durability in ballistic shock, high humidity, or desert conditions (e.g., night vision and target acquisition).

- Nuclear & Radiation Environments

Lead-shielded or radiation-resistant housings for infrared equipment in nuclear facilities or decontamination zones, protecting against ionizing radiation while monitoring heat signatures.

In each application, infrared protective housing ensures:

- Reliability: Sustained performance in extreme temperatures (-40°C to +85°C+), moisture, or dust.

- Safety: Compliance with explosion-proof (ATEX/IECEx), EMI/RFI shielding, or radiation protection standards.

- Accuracy: Unimpeded infrared signal transmission via high-transmittance windows (e.g., germanium, zinc selenide).

- Cost-Efficiency: Reduced maintenance and replacement costs in hard-to-access or hazardous locations.

By adapting to these diverse environments, infrared protective housing enables critical thermal monitoring across industries where unprotected equipment would fail or pose safety risks.